- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

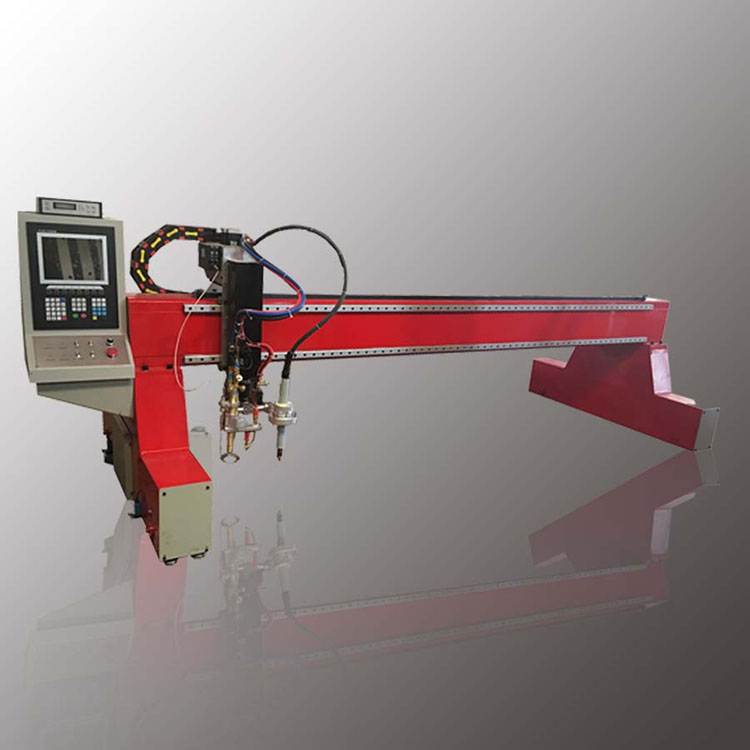

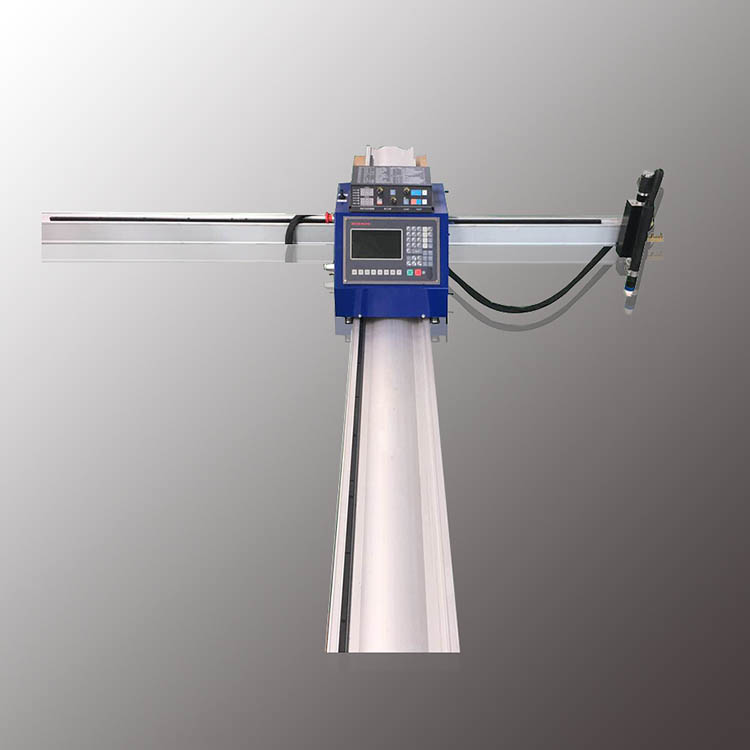

CNC Plasma Tables Plasma Cutter

Welcome to buy SUNNA plasma cutting machine, as the leading plasma cutting machine manufacturer and supplier in China, this CNC Plasma Tables Plasma Cutter is specially designed for high-quality cutting for precise metal processing. Welcome to purchase.

Send Inquiry

1. Industrial Industrial Plasma CNC Cutting Machine

Sunna is a leading China CNC Plasma Tables Plasma Cutter manufacturer, supplier and exporter. SUNNA CNC plasma cutting tables are designed for high-quality cutting. Compared with traditional cutting equipment, our industrial plasma cutting machine series adopts an integrated fully welded steel frame to ensure high precision, long service life and greater processing capacity. . What’s even more amazing is that these machines can use up to 400 amps of power, giving you an even wider range of cuts.

Each CNC plasma cutting machine uses a helical rack and pinion drive system for the X- and Y-axes, while the shorter Z-axis travel uses precision-ground ball screws to ensure high operating accuracy of the equipment. At the same time, through automatic height control technology, the machine is able to maintain appropriate height gaps for the cutting torch at different positions, thereby ensuring the stability and consistency of cutting quality.

This industrial plasma CNC cutting machine has been widely used in metal industry, machinery manufacturing, construction and other fields. Not only do they speed up the cutting process, they also significantly improve cut quality. With the help of high-efficiency industrial plasma cutting machines, companies can easily solve production problems.

2.Advantage of Industrial Plasma CNC Cutting Machine

1. Welded structure of thickening square tube, together with top brand guide rail to ensure high running speed and accuracy.

2. HUAYUAN LGK plasma power supply together with high sensitive arc pressure adjuster. Self-adjusting can choose the best distance between plasma gun and working piece automatically to ensure high accuracy cutting.

3. High definition CNC pasma cutters for sheet metal uses STARFIRE control system with FastCAM software for auto material saving function, large capacity storing function, convenient to read and process.

4. Cutting head with cooling system can quickly cool surface of material to avoid burr and residue.

5. Overall Leadshine stepper motor with high precision rack and pinion, to ensure the cnc plasma cutter has small noise, smooth, precise coordinates of the mobile performance.

6. Perfect software compatibility, such as Ucancam, Type 3, Artcum, etc.

3. Product Parameter (Specification)

| No. | Industrial Plasma CNC Cutting Machine | |

| 1 | Model | SN-1530P |

| 2 | Power source | AC 220/380±10%VAC 50/60Hz |

| 3 | Cutting mode | Plasma |

| 4 | Effective cutting range(mm) | 1500*3000 |

| 5 | Input Voltage | 220V, 50HZ |

| 6 | Cutting speed(mm/min) | 0-8000mm/min |

| 7 | Cutting thickness(Flame)(mm) | 6-160 (O2/C3H8 or C2H2) |

| 8 | Move precision | ±0.2mm/m |

| 9 | Torch | Flame, electric height adjustment(±60mm) |

| 10 | Processing thickness(mm) | 0.5-30mm |

| 11 | Cutting system | Starfire control system |

| 12 | Height control | THC (Torch Height Controller function) |

| 13 | Cutting thickness | According to the power supply( 4-200mm) |

| 14 | Cutting gas | Air |

| 15 | Gas pressure | 0.4-0.8Mpa for normal plasma power |

| 16 | Servo motor | Stepper Motor and driver /Servo (Optional) |

| 17 | X, Y axis | High Quality Rack & Pinion and Taiwan linear rail |

| 18 | Power | 40A/45A/60A/63A/65A/85A/100A/120A/160A/200A |

| 19 | Voltage | 220V/380V |

| 20 | Processing Materials | Iron, steel aluminum sheets, galvanized sheets, Titanium plates |

4. Industrial Plasma CNC Cutting Machine Main Parts Introduction

Torch Height Controller

Sunna is for controlling position of the torch relative to the material being cut.The torch height control uses arc voltage to maintain a consistent distance from the plate while the torch is cutting.

Starfire Plasma Control System

Applied torch plasma cutting technology, able to perform corner speed control and height control automatically.

Liner guide

Taiwan Hiwin linear guide and transmission to make sure the high accuracy

Fastcam Software

Some Standard patterns included and Auto Nesting to save more materials

High Quality Domestic HUAYUAN Plasma Source

High efficiency plasma generator result high precision and efficient cutting performance.

Electrode and Nozzel

We suggested to buy extra sets of electrode and nozzel as spare parts(The price is $5/set, includes 1pc nozzle and 1pc electrode, You can buy extra 20~30sets as a standby)

5. Applicable Industry and Materials

Sunna Industrial Plasma CNC Cutting Machine is often used in fabrication shops, automotive repair and restoration, industrial construction, and salvage and scrapping operations.Typical materials cut with a plasma torch include steel, stainless steel, aluminum, brass and copper, although other conductive metals may be cut as well.

6. Package and Delivery for Plasma Cutting Machine

SUNNA INTL has been cooperating with several big transport agents and shipping companies for long terms, and all machines are packed with standard plywood case for export, it can be transported to you safety as soon as possible.

International Shipping Term

All the CNC machines can be shipped worldwide by sea, by air or by international express logistics via DHL, FEDEX, UPS. You are welcome to get a free quotation by filling up the form with name, email, detailed address, product and requirements, we will shortly contact you with the full information including the most suitable delivery method (fast, secure, discreet) and freight.

CNC Plasma Cutting Machine After Sales Service:

1--SUNNA INTL is a company that focuses on research and manufacture of modular CNC machines. We have very rich experience and strong machine tool research and development capability. We are very willing to offer you customized highly-efficient equipment as long as you have a certain amount of needs.

2--We will supply cnc plasma cutters with training videos and user's manuals in English for installing, operation, maintenance and trouble-shooting, and shall give technical guide by e-mail,whatsapp,wechat,telegram,teamviewer,telephone and so on, when you meet some problems of installation, using or adjusting.

3--You can come to our factory for training. SUNNA will offer professional guide. Direct and effective face-to-face training. Here we have assembled equipments, all sorts of tools and testing facility,we will also provide accommodation during training period. Training Time: 1-10 working days.

4--For the out of warranty machine which needs to replacement parts, we will charge according to the parts quotation. If you have any questions, please email us for consultation.

SUNNA has state-of-the-art technology to design and manufacture CNC cutting machines to provide customers with superior end products. Whether your business is a small shop, heavy equipment manufacturer, or steel service center, we have high-performance cutting machines, also OEM and custom designs, to meet all your needs.