- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

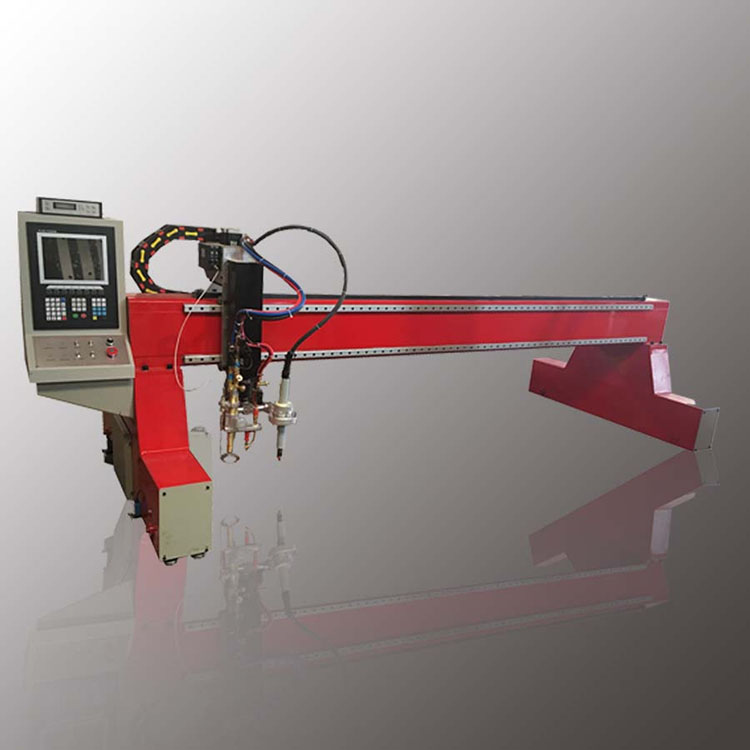

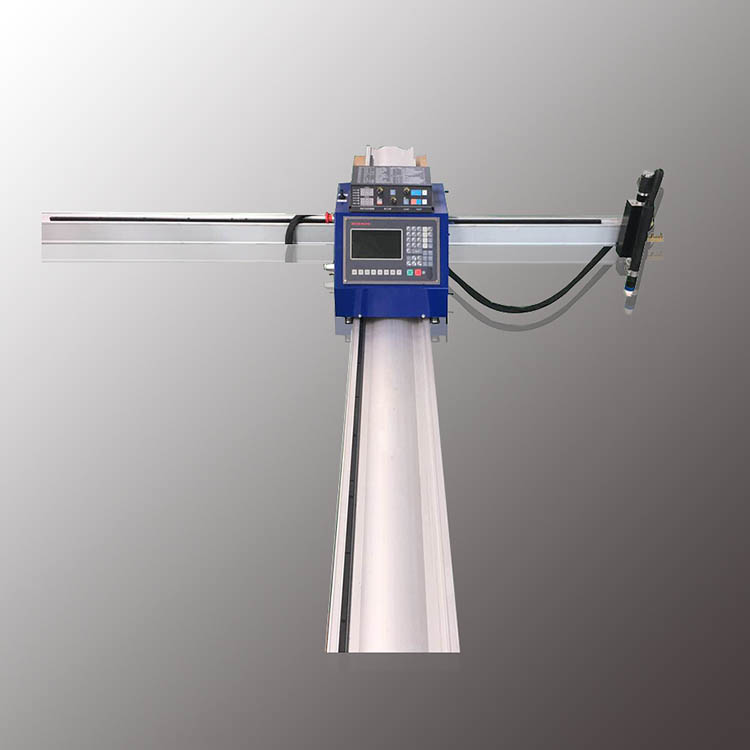

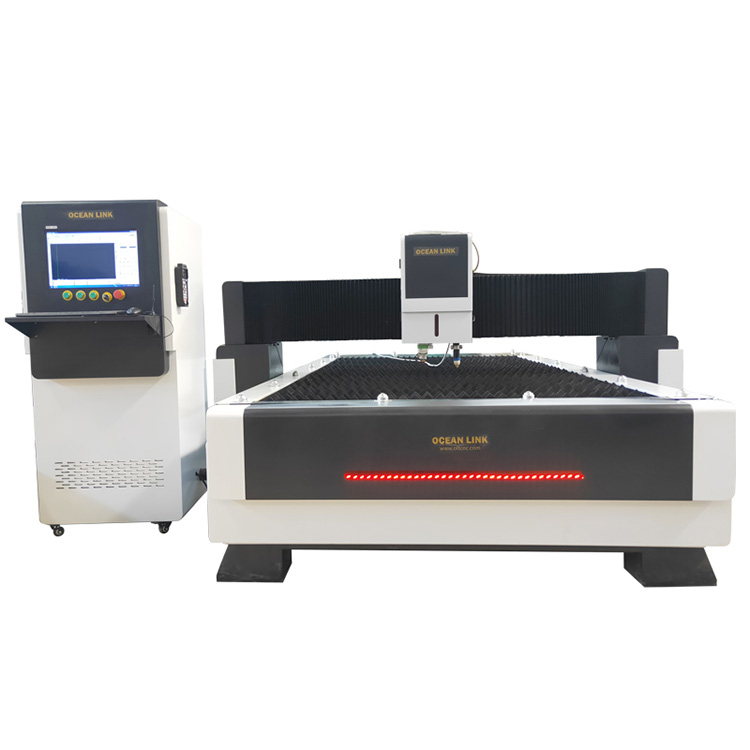

Industrial Gantry CNC Plasma Cutting Machine

Industrial Gantry CNC Plasma Cutting Machine is a high-efficiency and energy-saving cutting equipment, suitable for precision cutting and blanking of carbon steel, stainless steel and non-ferrous metal plates of various thicknesses, improving the utilization rate of plates, saving time and materials. Flame cutting can cut 0-200mm stainless steel, carbon steel and non-ferrous metals to achieve high-quality cutting.

Send Inquiry PDF DownLoad

The structure and configuration list

Industrial Gantry CNC Plasma Cutting Machine is specially designed for sheet metal cutting, featuring high degree of automation, high efficiency, convenient operation and long service time. The plasma cutting machine is a gantry structure, double drive system, and the working size can be customized according to needs. It can be used to cut any two-dimensional graphics of carbon steel, stainless steel and non-ferrous metals, and the gantry plasma cutting machine is widely used in the field of metal cutting.

Gantry plasma cutting machine features:

1) The beam is designed with lightweight structure, with good structural rigidity, light weight and small motion inertia.

2) Gantry type structure, Y axis adopts dual motor dual drive system, X, Y, Z axis adopts double straight line, so that the machine runs smoothly and has high precision.

Completely solve the traditional manual processing methods. The efficiency is increased several times.

1-Seamless welding machine body

2-Working area: 3000*6000mm

3-Huayuan LGK plasma source(Power optional:63A,100A,120A,160A,200A,300A)

4-Industrial flame cutting system

5-FangLing 2300B control system

6-Automatic torch height control

7-Starcam software

8-High precision Square guide rail

9-Rack and Gear transport system

10-Multi-function tool box

Advantage of Industrial Gantry CNC Plasma Cutting Machine

1--The painting: all our machine body have been processed by professional anti-rust treatment. First, we spray 2 times anti-rust paint to ensure that all parts of the machine in a fully protected state, and then spray color. This can effectively prevent the machine rust, resulting in damage to the machine. Other manufacturers do not take anti-rust treatment or only spay 1 time rust paint.

2-Software: our software have self-adjust function. That means, when you put the metal sheets slide, the software will adjust the cutting according to metal sheets direction, so that it will protect the metal sheets and good cutting results. Especially when cut large or expensive metal sheets, this will preventing big loss.

3-Our machine support many languages, like English, Russia, Spanish etc. Then the clients can operate the machine more convenient.

4-When cutting many drawings, our software can automatically sort and achieve best combination, so that the machine can cut all drawings in shortest time.

5-We use super soft shielded cable to ensure that the plasma power supply does not affect the motor during working.

6-Just because our machine all equipped the professional parts, and test more seriously for the whole machine, so our guarantee period it is 2 years.

Product Parameter (Specification)

The basic configuration

| The serial number | The project name | The number of | Instructions |

| 1 | Cutting way | Plasma/flame | |

| 2 | Guide spacing | 3000/4000/6000mm (customizable) | |

| 3 | Guide rail length | custom | |

| 4 | Transversely moving body | JL2021 lifting body | |

| 5 | Automatic programming nesting software | 1 set of | Nest smart nesting |

| 7 | Arc pressure heightening device | Shanghai Jiaotong University F1621 | |

| 8 | system | 1 set of | Shanghai Jiaotong University F2300B |

| 9 | System cabinet | 1 set of | custom |

| 10 | Servo motor | Three groups | Taiwan Delta Y-axis 750W X-axis: 400W |

| 11 | reducer | 3 sets of | Han, 80-40 |

| 12 | hang | 1 set of | Contains 10 small pulleys |

| 13 | To track | 24KG (2 m/root) | |

| 14 | Lateral drive system | 1 set of | Precision rack and pinion single spindle core guide rail |

| 15 | Horizontal drag chain | 1 set of | 35 x100 bridge type |

| 16 | Lifting body towing chain | 1 set of | 35 x100 bridge type |

| 17 | Plasma fixture | ||

| 18 | Anti-collision device | 1 set of | |

| 19 | Steel belt drive | 1 set of |

Technical indicators

| The serial number | The project name | Indicators |

| 1 | Effective cutting width | Or less |

| 2 | Effective cutting length | Or less |

| 3 | Idle travel speed | 0-12000mm/min |

| 4 | Plasma cutting material | Carbon steel, stainless steel |

| 5 | Plasma cutting thickness | Or less |

| 6 | Plasma perforation thickness | Carbon steel or less |

| 7 | Plasma cutting speed | 0-6000mm/min |

| 8 | Plasma cutting torch lifting distance | 250 mm or less |

| 9 | Plasma cutting torch lifting mode | Automatic rise and fall of arc voltage |

| 10 | Side straightness of dominant rail | 0.4 mm / 10000 mm |

| 11 | Side straightness of auxiliary guide rail | 1mm/20000mm |

| 12 | Parallelism of longitudinal plane and horizontal plane of main and auxiliary guide rail | + / - 0.2 mm / 1000 mm |

| 13 | Cutting torch lifting verticality tolerance | + / - 0.2 mm |

| 14 | Intersection offset allowance | + / - 0.5 mm |

| 15 | Tolerance of straightness | + / - 0.2 mm |

| 16 | Roundness tolerance | + / - 0.5 mm |

| 17 | Diagonal tolerance | + / - 0.5 mm |

| 18 | Plasma cutting acceptance criteria | Conformity with JB/T10045.4-1999 |

| 19 | Machine accuracy acceptance standard | Conformity with JB/T5102-1999 |

Industrial Gantry CNC Plasma Cutting Machine Details

-

Torch Height Controller

It is for controlling position of the torch relative to the material being cut.The torch height control uses arc voltage to maintain a consistent distance from the plate while the torch is cutting.

-

Shanghai FangLing 2300B control system

The control system has a graphic display function, which can observe the cutting process in real time. And supports 9 languages, it is easier to use your own native language to operate. With power-off memory function, you can continue cutting after the power on, saving time for cutting from the beginning. There are 48 kinds of graphics, regular graphics can be directly used, change the size, set the quantity, save the computer drawing time and improve efficiency.

-

Switch cutting mode immediately

When using multiple lifting bodies, connect them with stainless steel belts to adjust the distance between the two lifting bodies and make the cutting mode change quickly.

-

Fastcam Software

Some Standard patterns included and Auto Nesting to save more materials

-

High Quality Domestic HUAYUAN Plasma Source

High efficiency plasma generator result high precision and efficient cutting performance.

-

Electrode and Nozzel

We suggested to buy extra sets of electrode and nozzel as spare parts(The price is $5/set, includes 1pc nozzle and 1pc electrode, You can buy extra 20~30sets as a standby)

Applicable Industry and Materials

CNC Plasma Sheet Metal Cutting Machine is suitable for all kinds of sheet metal materials such as steel, copper, aluminum and stainless steel can be processed. It is used for aluminum plate, stainless steel, galvanized sheet, white steel plate, titanium plates, and so on like the sheet metal.

Package and Delivery for Plasma Cutting Machine

SUNNA INTL has been cooperating with several big transport agents and shipping companies for long terms, and all machines are packed with standard plywood case for export, it can be transported to you safety as soon as possible.

International Shipping Term

All the CNC machines can be shipped worldwide by sea, by air or by international express logistics via DHL, FEDEX, UPS. You are welcome to get a free quotation by filling up the form with name, email, detailed address, product and requirements, we will shortly contact you with the full information including the most suitable delivery method (fast, secure, discreet) and freight.

Sunna CNC Plasma Cutting Machine After Services

1. Mature service:

Pre-Sales Service:Inquiry and consulting support, Free making samples support,View our Factory. After-Sales Service :24 hour technical support by email , telephone or online video ,User friendly English manual for machine using and maintaining, Training how to install the machine and use the machine, Engineers available to service machinery overseas.

2. large machine factory and large quantity producing ability, which can satisfy clients’ large order in short time.

3. We adopt the strength export wooden case, for shipping. It is efficiently protect the machine in good situation after long term transportation.

4. Customers don’t have to worry about installation, we provide foundation drawings for free.

5. We have details video can show every part of the operation, so after you getting the machine ,and operate in time, and we can also totally according your requirement to do the video only for your job

SUNNA takes all aspects of security training very seriously to ensure that you fully understand how to use the machine safely. For all our customers, we offer life-long email and telephone technical support. The service is completely free and is available from 09:00 to 17:00 Monday to Friday. Whether you're having problems with your machine, having trouble converting your files to the proper format, or want some advice on how best to deal with some material you haven't used before, we're here to help.