- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

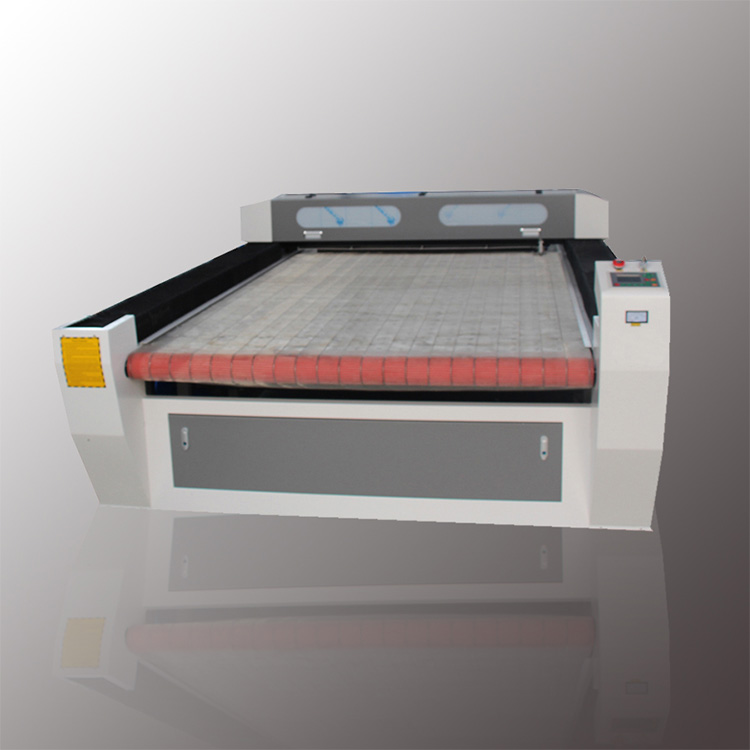

CNC Laser Fabric Cutter Advantages

CNC Laser Fabric Cutter Advantages are highly versatile, so investing in a CNC Laser Cutting Machine can help you meet a wide range of requirements. They can cut a range of different materials, including acrylic, cardboard, fabric, textiles, wood, leather, MDF and even some sheet metals.

Send Inquiry PDF DownLoad

What is Laser Fabric Cutter?

SUNNA CNC Laser Fabric Cutter Advantages:

Laser cutting machines are highly efficient and design replicas are the exact copies of each other.

It requires and consumes less amount of energy to cut sheets of all types of materials.

In comparison with the traditional scissors, laser cutting machines take less time to cut large sheets and the outcome is extremely accurate.

The entire process is monitored by the computer programs which reduce the amount of work and workload.

Much human intervention is not required except for maintenance and observation. No danger of accidents or injuries

Very flexible, can be used to cut almost all types of materials.

Precise cuts can be obtained within short time.

automatic feeding system is suitable for cutting fabric, garment, textile, leather, cloth in home shop and small business. Now the affordable fabric laser cutter for sale at cost price.

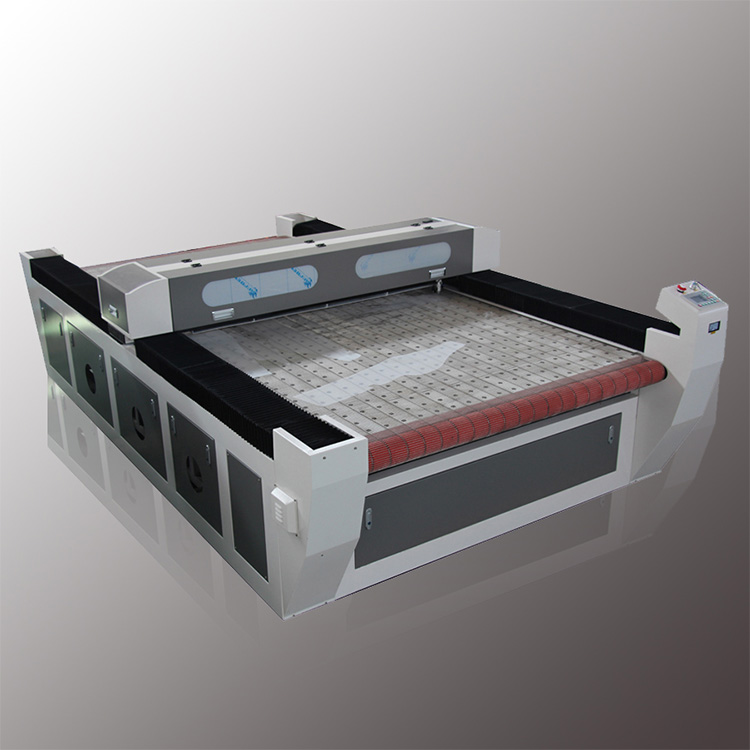

Laser fabric cutter is a type of CO2 laser cutting system that uses high-energy-density laser beams to complete rapid cutting work on clothing fabrics. Fabric laser cutting machines are widely used in the textile and garment industry. Laser fabric cutting machines are applied to cut fabrics, lint free cloth, linen, cotton, chemical fiber, woven fabrics, lace, leather, mesh, trademarks, clothing accessories, and more flexible fabrics.

CNC Laser Fabric Cutter Advantages

Fabric laser cutting machine has the advantages of convenient and fast, flexible conversion, accurate and efficient, energy saving and environmental protection in the cutting of clothing fabrics, so it is favored by users in the textile and clothing industry.

No Burr/Fraying with Laser Fabric Cutting

Laser fabric cutting is done by high temperature process. It can make the cutting edge to close up automatically. Hence, no need to recut the fabric patterns after one-time cutting.

No Distortion To Cut Fabric

In the process of cutting, laser dose not touch the processed fabric, but laser beam works on the fabric.

High Precision

Diameter of the laser beam can be focalized into 0.1mm. Cutting is done exactly according to uploaded graphics through computer control.

High Efficiency & Easy Operation

Just upload the graphics into the cutting machine and laser will cut fabric into shapes as designed.

Specification

| Modle | SN-1626C |

| Working Area | 1600mm*2600mm |

| Laser Power | 60W/80W/100W/130W/150W |

| Laser Type | CO2 Sealed Laser Tube,10.6um |

| Cooling Type | Water Cooling |

| Engraving Speed | 0-20000mm/min |

| Laser output Control | 0-100% Set by Software |

| Min. Engraving Size | Chinese:2.0mm*2.0mm,English Letter:1.0mm*1.0mm |

| Scanning Precision | 2500DPI |

| Locating Accuracy | -+0.01mm |

| Controlling Software | DSP Control System |

| Graphic Format Supported | DST PLT BMP DXF DWG AI LAS,ect. |

| Compatible Software | TAJIMA,CORELDRAW,PHOTOSHOP,AUTOCAD,All type of AUTOCAD Software in Cloth |

| Color Separation | Yes |

| Drive system | High-precision 3-phase Stepper Motor |

| Auxiliary Equipment | Exhaust Fan and Air Exhaust Pipe |

| Power Supply | AC110V/220V,50HZ/60HZ |

| Working environment | Temperature:0-45℃,Humidity 5-95%(No Condensate Water) |

| Option | Up and Table,Honeycomb Worktable,Rotary Device,Red Dot Position System,Auto-focus Device |

Details:

-

1/ Fabric laser cutting machine adopts an automatic feeding system for home use and small business, no manual feeding is required, which saves time and effort. Automatic typesetting is also applied to the machine, and typesetting is based on the most material-saving method, which saves time and effort, saves materials, and reduces waste. The rolls of the laser fabric cutter are able to roll up the large material automatically. Improve the working efficiency greatly.

-

2/ Adopt high speed Linear motion guide, ensuring the laser head is moving smoothly, fast and stable. Small cutting kerf, high cutting speed and accuracy guarantee the equipment’s precision and lifetime.

-

3/ Ruida RDC6445G Control System

● 5 inch big LCD display.

● With Z+/Z- buttons, one button control up down of worktable.

● With U+/U- button, one button feed material in rolls like fabric, leather, paper.

● With "Focus" button, one button control auto focus the worktable suit for different thick material.

● With 0-9 numbers, easy set parameters for files. -

4/ The Industrial chiller CW5000, ensuring the CO2 laser tube long time continue working.

Application

Fabric laser cutting machine is suitable for plush toy cloth processing, clothing processing industry, leather processing industry.

Co2 Laser Engraving and Cutting Machine After Sales Service:

1.All of co2 laser Machine will be fully-checked by our quality control department before the shipment.We guarantee all of machines have a two -years warranty.

2.Training details: operation principles, system and structure, safety and maintenance, software the processing technique, and so on.

3. Numerous feedback from our clients have proven that our laser machines are stable in performance with rare malfunction. However, we would like to handle it as follows function occurs:

a.We guarantee that we will give you a clear reply within 24 hours.

b. Customer service staff will assist and guide you to analyze the malfunction in order to locate the cause.

c. If the malfunction is caused by improper operation on software and other soft faults, we will help solve the problem online.

d.We will offer plenty of online supports, just like detailed technical and installation instructions by email,video, whatsapp,wechat (Training by team viewer)

ODM/OEM customized projects allocate sufficient resources to ensure the first response, efficient collaboration with customers, shorten the research and development cycle, and help customers quickly realize product marketization. Wecome to contract us