- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

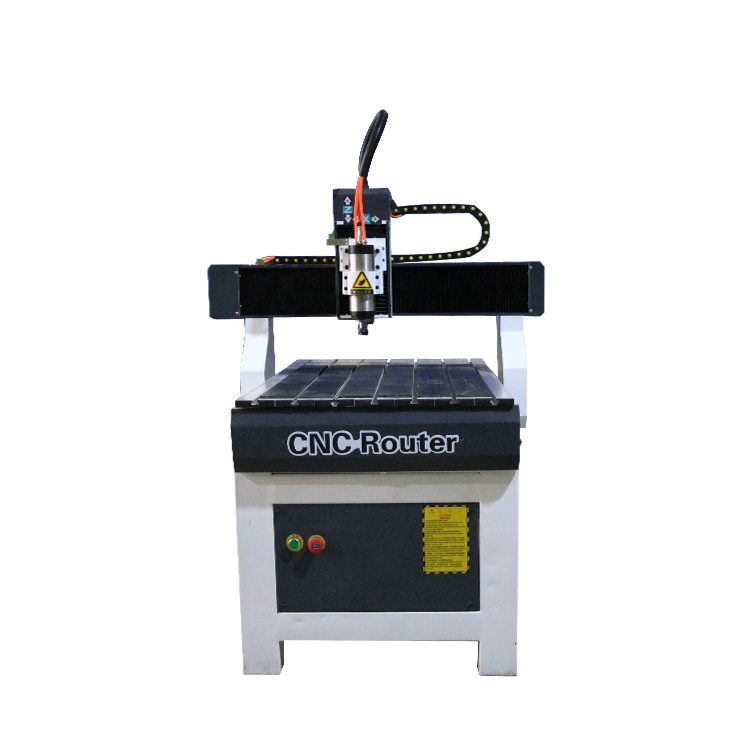

3D Dynamic RF Galvo Laser Marking Machine

3D Dynamic RF Galvo Laser Marking Machine which is suitable for marking and coding metal materials such as flat surfaces, curved surfaces, high ground, inclined surfaces, and irregular surfaces.

Send Inquiry PDF DownLoad

1. Product Introduction

The 3D Dynamic RF Galvo Laser Marking Machine adopts the three-axis Dynamic system to bring a wider working range and automatically mark the surface of the workpiece with different heights at one time. By importing the pre-designed 3D model and setting some necessary parameters, precise control of 3D carving can be achieved.

This 3D Dynamic RF Galvo Laser Marking Machine uses co2 laser source with the wavelength of 1064nm. This design can meet the requirements of different applications: marking, engraving, cutting, color removal, paint treatment, material micro heat treatment, etc.

It can be used for fixed workbenches and production lines to meet the characteristics of the system.

The machine adopts aluminum structure and is controlled by the latest drive in the entire working area to achieve stable quality.

The laser path change is driven by two galvo motors (XY), the third axis is driven by the pre-scanning focusing system so that the focus distance can be widely adjusted.

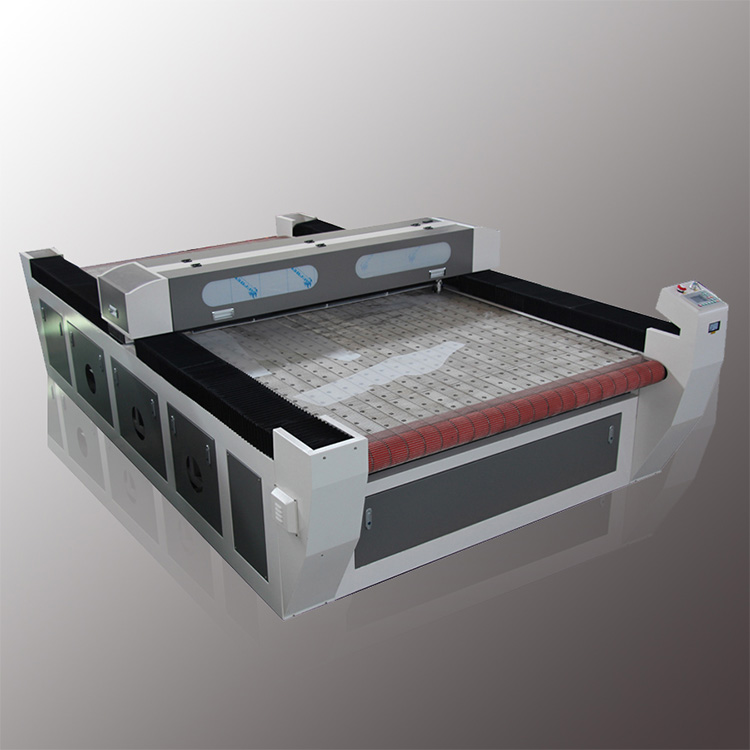

2.Structure

The control parts are concentrated in control cabinet, and the optical components of the whole machine are concentrated in the optical main beam and the inside of the square head through a complete optical path design. The integrated chiller provides the cooling water system for the normal operation of the whole machine. The 3D Dynamic RF Galvo Laser Marking Machine includes the following main parts:

► Optical system

► Cryogen system

► Electrical control system

► Industrial computer and control card

► Marking control software

► Electric lifting table

► Security door

3. Product Parameter (Specification)

| Model | SN-F |

| Galvo Scanning System |

Speed: 10000mm/S Repeat positioning accuracy: 0.005 Maximum scanning speed: 10000mm/s |

| Laser Source | Nanjing crdlaser 180D Max.Power:At least 205W Peak power: 350W |

| Focusing System | 3D Dynamic Focusing system 400-800mm range |

| Marking Area |

(400mm×400mm~500*500mm)--800mm×800mm (Freely adjustable range) |

| Optical Lens | Nanjing wavelength |

| Max.Cutting Thickness | 3mm |

| Maximum lifting height | Height of electric lifting table 400mm-800mm |

| Cooling model | High-precision constant temperature water cooling (compressor) 1.5P |

| Total Power | Max. 6KW |

| Working Voltage | 220VAC/10A/50-60HZ |

| Software |

JCZ Enhanced version with rotation function (With bitmap mark function) 2.14.11 version |

| System Requirement | WIN7 64-bits flagship version |

| Environmental | 15℃-30℃,Humidity 30-80%,No condensation |

| Total Weight | 160KGS |

| Machine Dimension | 900*1200*1600mm |

4. Product Feature and Application

Application

The high-performance optical transmission system coupled with the excellent optical mode enables the machine to engrave and mark a variety of materials, such as: marble, wood, glass, leather, textiles, paper, plastics (acrylic, acetate, synthetic fibers, PE, PT, PVC) and other materials. The good optical quality also brings an important property of being able to mark on metal surface coatings such as: anodized aluminum materials and metal stainless steel, etc., in addition to cutting on thin materials such as paper, leather, textiles,denim jeans,acrylic,wood,etc.

Machine Features:

3D Dynamic RF Galvo Laser Marking Machine using dynamic focus technology, the focused spot is finer, faster, it’s suitable for large-format marking or cutting, and has the following advantages:

① There is no need to change different lenses to obtain different marking ranges, and the focused spot is finer.

② Fully enclosed maintenance-free laser optical system, no need to adjust, just install and use directly.

③ High-precision, high-speed marking/cutting performance, work efficiency is 20% higher than similar models

④ The professional constant temperature circulating industrial water cooling system makes the whole machine run more stable and consume less power.

⑤ Multi-protection control design, applicable to a wide range of ambient temperatures, to ensure the 24-hour continuous and reliable operation of the laser marking system.

⑥ Application system, compatible with AutoCAD, CorelDraw, Photoshop and other software file formats, such as DXF, PLT, BMP, etc.

Installation requirements:

1. Power requirements: 220V, stability within 5%, two-phase three-wire well grounded, maximum power consumption 6kw.

2. Environmental requirements: It must be equipped with a high-precision isolation voltage stabilizer above 10KW, no strong electric and strong magnetic interference, no vibration area, well-installed ground wire, avoid direct sunlight, operating environment temperature 15℃-30℃, humidity 35%-80 % No condensation, operating altitude <3000 meters.

Machine sales service

The whole machine is guaranteed for 2 years from the date when the product arrives at buyer place. If the parts are damaged within 2 years (except for human factors and force majeure),the supplier is responsible for free repairs, and replacement parts are provided by the supplier free of charge.(Damage to optics and other components caused by the use environment or use is not covered by the warranty),normal consumables components (such as: lens protection window,grid,foot switch,air duct, computer keyboard, mouse) are not covered by the warranty.

Machine Application

SUNNA will provide a strong scale of sales and service network, to assist you in local marketing, and to create a larger customer group. SUNNA welcomes you to join us.