- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

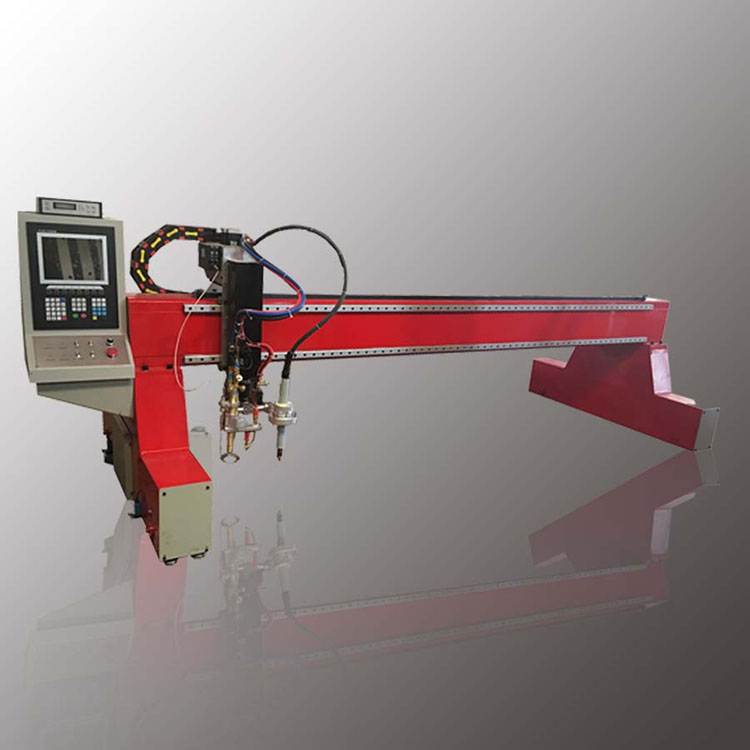

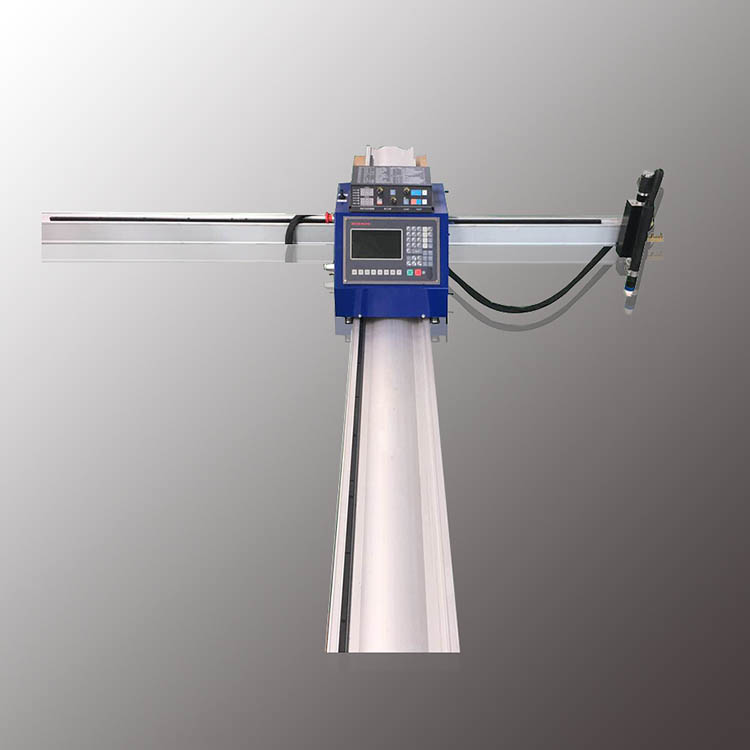

CNC Gantry Plasma Flame Cutter

The SUNNA cnc gantry plasma flame cutter is a cutting-edge machine designed for precision cutting of a variety of metal plates, including carbon steel, manganese steel and stainless steel. This cnc gantry plasma flame cutter uses advanced technology to ensure clean and accurate cutting, high efficiency and reliability, making it an ideal choice for a variety of industrial applications. Experience the power and precision of SUNNA's cnc gantry plasma flame cutter and take your production to the next level.

Send Inquiry

Introducing our cnc gantry plasma flame cutter, designed for precise cutting of a wide range of metal materials, including carbon steel, manganese steel and stainless steel. This cutting-edge machine features a gantry design, and its portable design allows for easy transportation and setup, making it a versatile solution for on-site cutting tasks. With outstanding precision and efficiency, the SUNNA cnc gantry plasma flame cutter ensures smooth and clean cuts, is capable of cutting a wide range of metals and thicknesses, easily cuts intricate and delicate designs, and is suitable for cutting complex geometries such as curves, angles and holes, making it an ideal choice for a variety of industrial applications. Invest in a SUNNA cnc gantry plasma flame cutter and experience the difference in your metal cutting operations.

Product description of Gantry Type Metal Plate Cnc Plasma Cutting Machine

Gantry CNC cutting machine series of flame / plasma cutting machine is a high efficiency and high performance equipment, which uses gantry type, single drive or double drive. Its excellent cutting parameters, reliable and stable features ensure the perfect cutting effect. CNC flame/plasma torch has auto height regulator and auto ignition functions, which is convenient for use.

Gantry Flame and Plasma CNC cutting machine is mainly used in all kinds of metal plates (such as: carbon

steel, stainless steel, aluminum, low alloy steel, aluminum alloy), but also in the complex pattern.

1. formed by high-strength steel welding processing

2. 100% hardened bed to make the machine stable.

3. The machine has passed three-layer quality inspection, with high precision and long service life.

Product parameters of Gantry Type Metal Plate Cnc Plasma Cutting Machine

| Model | 2560 |

| X,Y working area | 2500*6000mm |

| Z working area | 300mm |

| Lathe bed | Very thick steel structure |

| Machine Power | 8.5kw |

| Working voltage | 380V/50HZ three phase |

| Reposition precision | 0.02mm |

| Processing precision | 0.1mm |

| Maximum cutting speed | 12000mm/min |

| Torch Height control mode | Automatic high sensitive THC |

| Plasma power supply | China LGK200A |

| Cutting thickness | Max40mm carbon steel for plasma, max300mm carbon steel for flame |

| Control system | SJTU-CNC control system |

| Motors | China brand stepper motor |

| Software | fastcam |

| Weight | 1600 KGS |

| Plasma Air Pressure | Max.0.8Mpa |

| Working Temperature | -10°C-60°C. Relative Humidity, 0-95%. |

| flame cutting | 300mm |

The sample photos

This plasma cutting machine are mainly used for various metal plates (e.g. carbon steel, stainless steel, aluminium, low alloy steel, aluminium alloy), but also for the processing of complex patterns.

The advantages of Gantry Metal Cutter Flame Plasma CNC Cutting Machine

1. We have detailed teaching video for customer, like step by step and hand by hand to teach how to use machine and software .etc, so even a freshman will learn machine using faster and easier. While most other factory only have word instructions, we met many customer misunderstand when read the word instruction and lead to operate wrong and damage the machine.

2. The painting: all our machine body have been processed by professional anti-rust treatment. First, we spray 2 times anti-rust paint to ensure that all parts of the machine in a fully protected state, and then spray color. This can effectively prevent the machine rust, resulting in damage to the machine. Other manufacturers do not take anti-rust treatment or only spay 1 time rust paint.

3.Software: our software have self-adjust function. That means, when you put the metal sheets slide, the software will adjust the cutting according to metal sheets direction, so that it will protect the metal sheets and good cutting results. Especially when cut large or expensive metal sheets, this will preventing big loss. While other factory machine does not have this function.

4.Our machine support many languages, like English, Russia, Spanish etc. Then the clients can operate the machine more convenient

5.When cutting many drawings, our software can automatically sort and achieve best combination, so that the machine can cut all drawings in shortest time.

6.We use super soft shielded cable to ensure that the plasma power supply does not affect the motor during working.

7.Just because our machine all equipped the professional parts, and test more seriously for the whole machine, so our guarantee period it is 2.5 years, while other factory it is only 1 years.

8.we will free provide 2G processing design, in the 2G processing design have thousand beautiful graphic, after you get the machine, you can let the machine do a lot of beautiful work, while no need find the engineer to help you to design.

Package and Delivery of Gantry Type Metal Plate Cnc Plasma Cutting Machine

SUNNA INTL has been cooperating with several big transport agents and shipping companies for long terms, and all machines are packed with standard plywood case for export, it can be transported to you safety as soon as possible.

Why most of the customer finally choose us after compared

1. Mature service:

Pre-Sales Service:Inquiry and consulting support, Free making samples support,View our Factory.

After-Sales Service:24 hour technical support by email , telephone or online video ,User friendly English manual for machine using and maintaining, Training how to install the machine and use the machine, Engineers available to service machinery overseas.

2. large machine factory and large quantity producing ability, which can satisfy clients’ large order in short time.

3. We adopt the strength export wooden case, for shipping. It is efficiently protect the machine in good situation after long term transportation.

4. We have details video can show every part of the operation, so after you getting the machine ,and operate in time, and we can also totally according your requirement to do the video only for your job .