- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Industry News

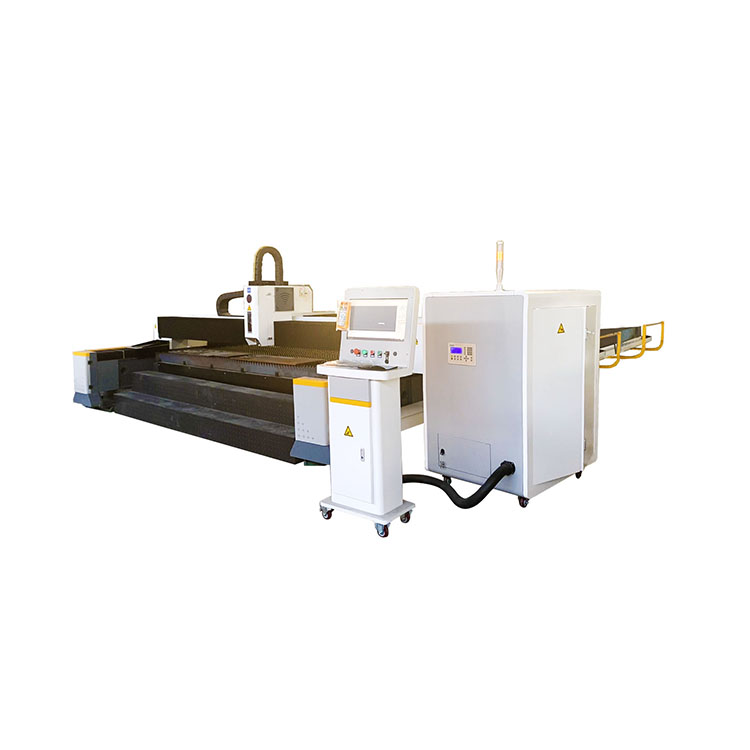

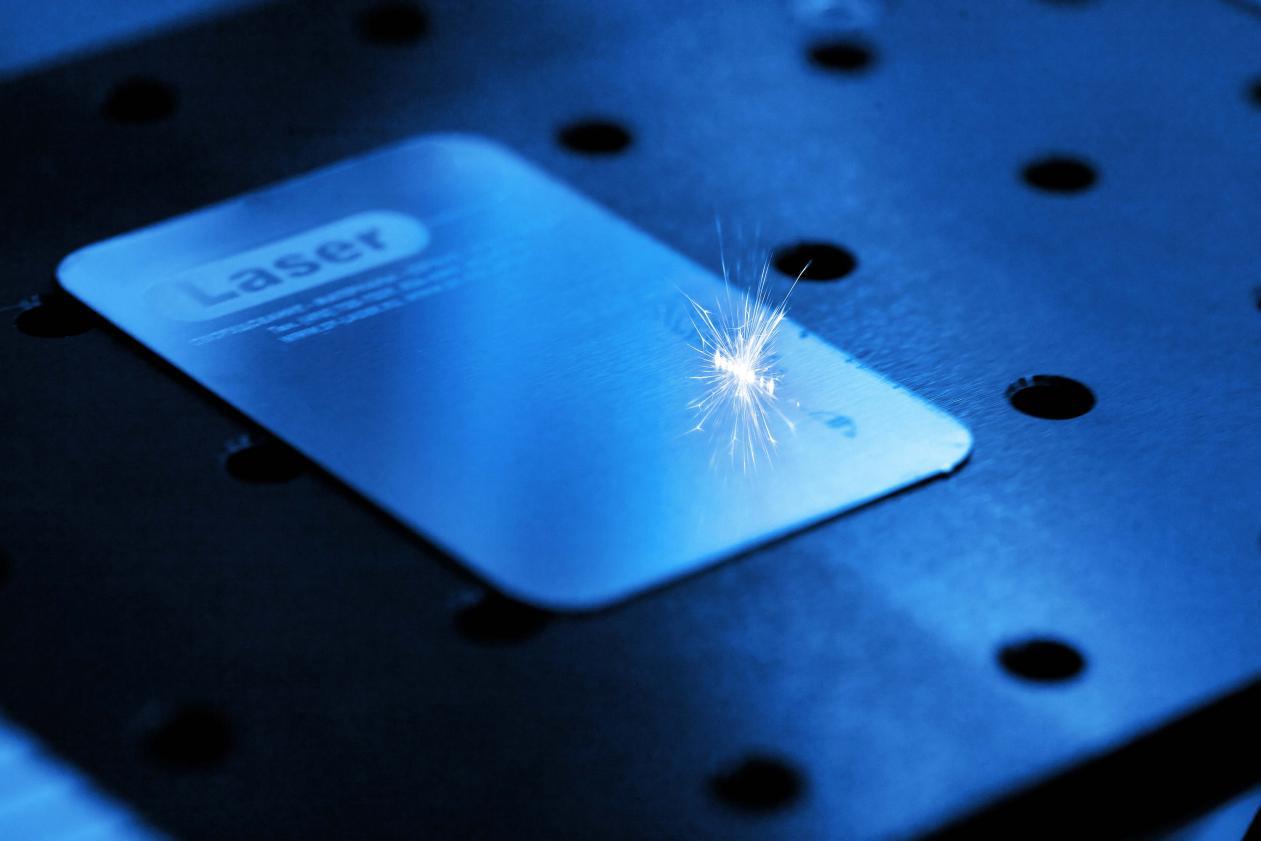

How does a fiber laser cutting machine work?

Laser beam generation: The process starts with the generation of a high-intensity laser beam inside a fiber laser resonator. The resonator consists of a fiber optic cable doped with rare earth elements such as erbium, ytterbium or neodymium. These elements enable the fibre to amplify light and produ......

Read MoreFactors affecting the cost of laser marking machines

As an efficient and accurate marking equipment, laser marking machine has been widely used in industrial manufacturing, medical equipment, electronic products and other fields. Its cost is directly related to the company's investment decisions and production efficiency. Understanding the factors tha......

Read MoreFactors affecting marking speed

The marking speed of a laser marking machine is affected by many factors, including material characteristics, laser parameters, optical system characteristics, environmental conditions, motion control, system integration, etc. Understanding these factors can help optimize marking speed and achieve t......

Read MoreAluminum Cutting Process: Hints and Tips

Metal cutting lubricants help reduce chatter and inconsistency during the cutting process and also help remove chips and swarf. The most common aluminum lubricant is WD-40, but other lubricants such as metal cutting wax and water are equally effective in preventing blade clogging.

Read MoreWhat does a CNC milling machine do?

CNC mills are an integral part of the manufacturing industry and their unique design sets them apart from vertical column mills without CNC. These CNC machines have a horizontally oriented spindle that accommodates the cutting tools, allowing chips to come off faster and making these milling machine......

Read More