- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

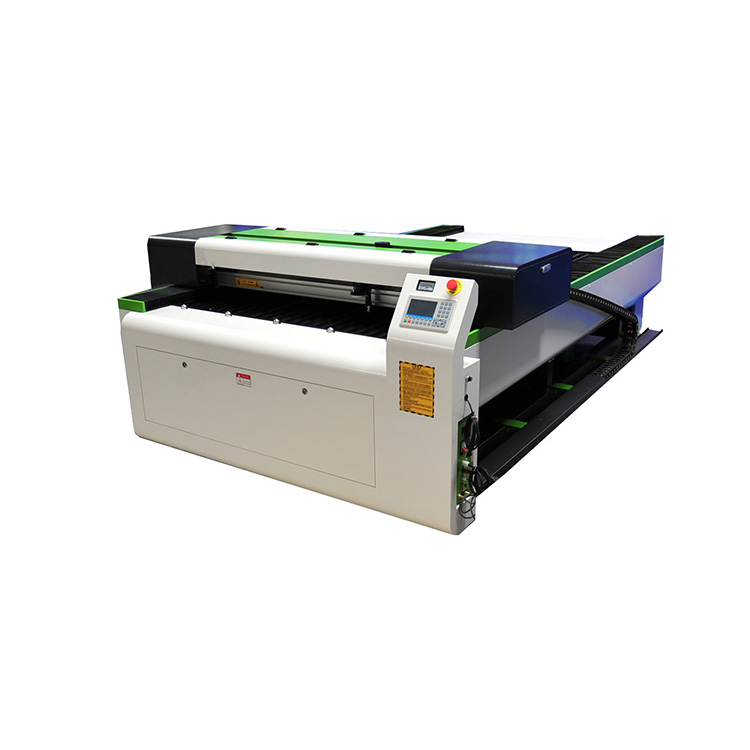

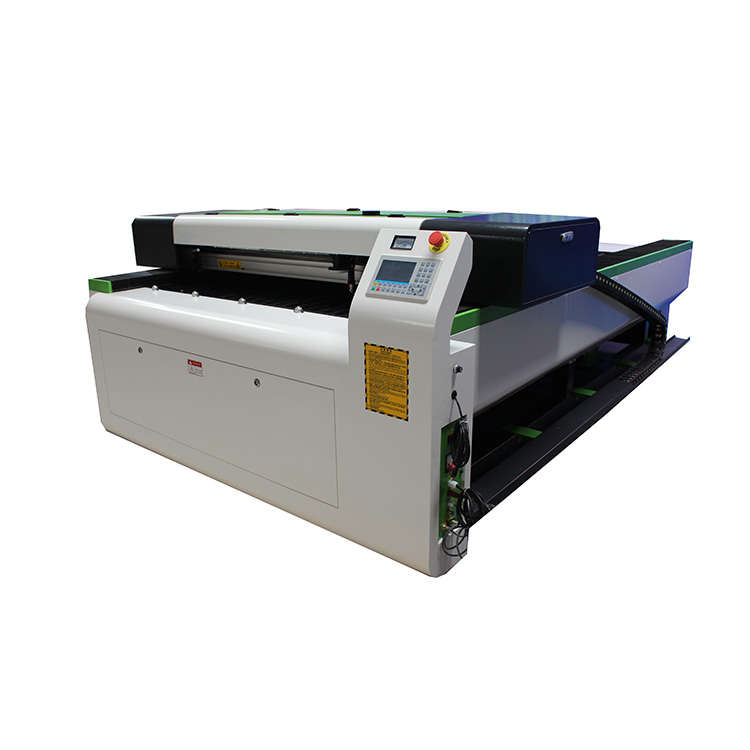

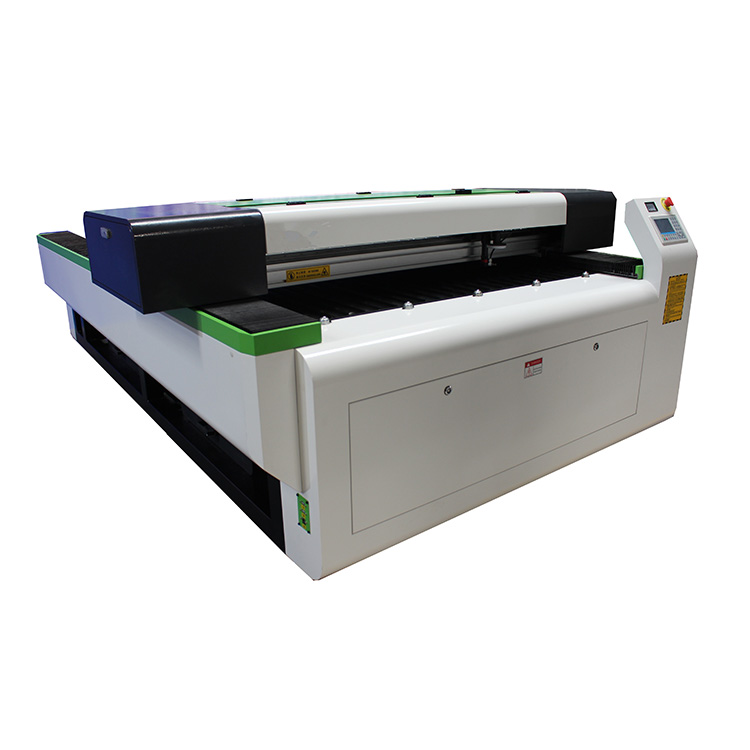

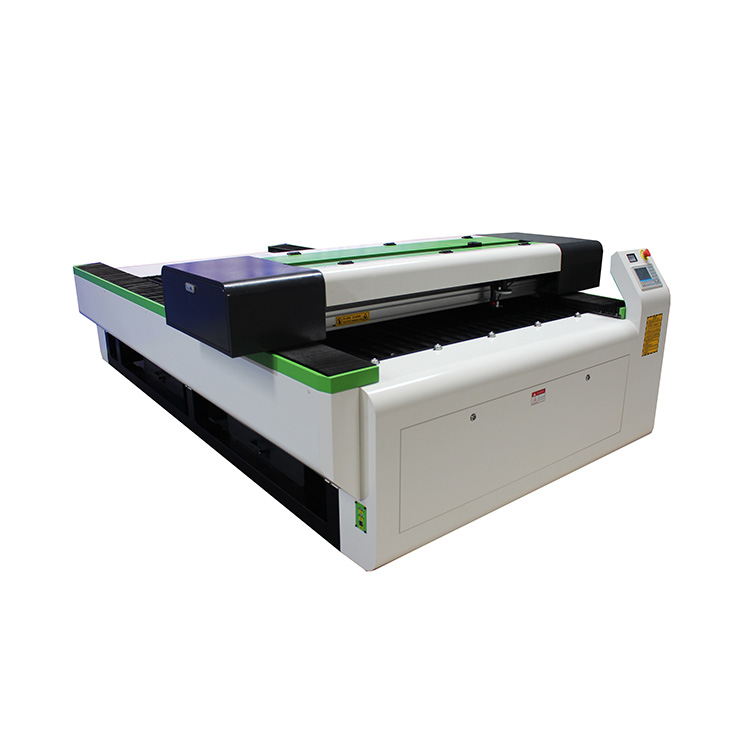

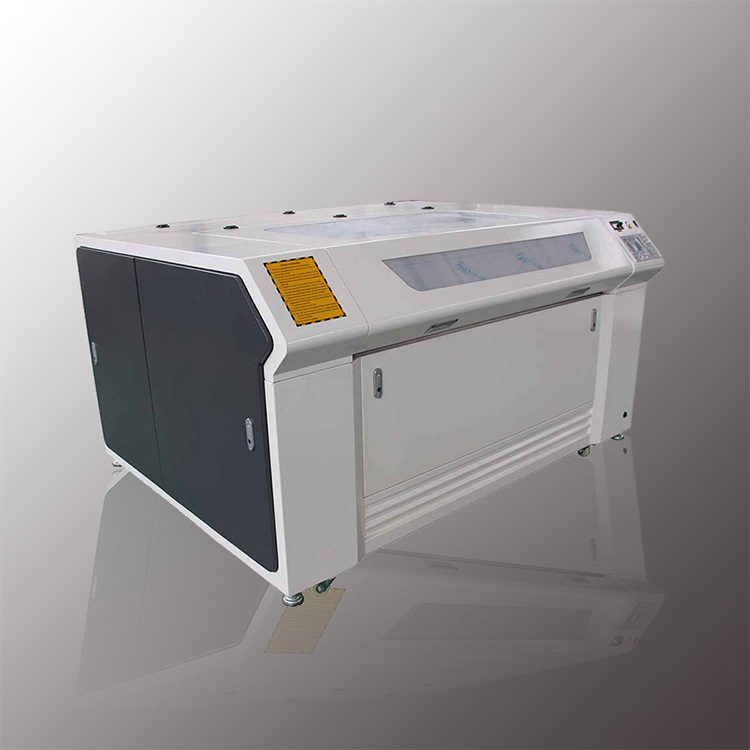

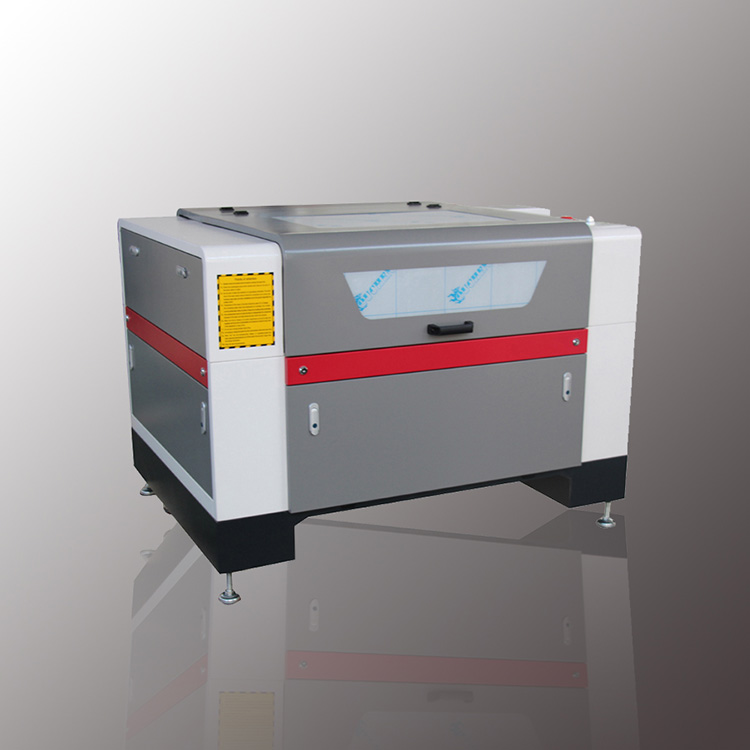

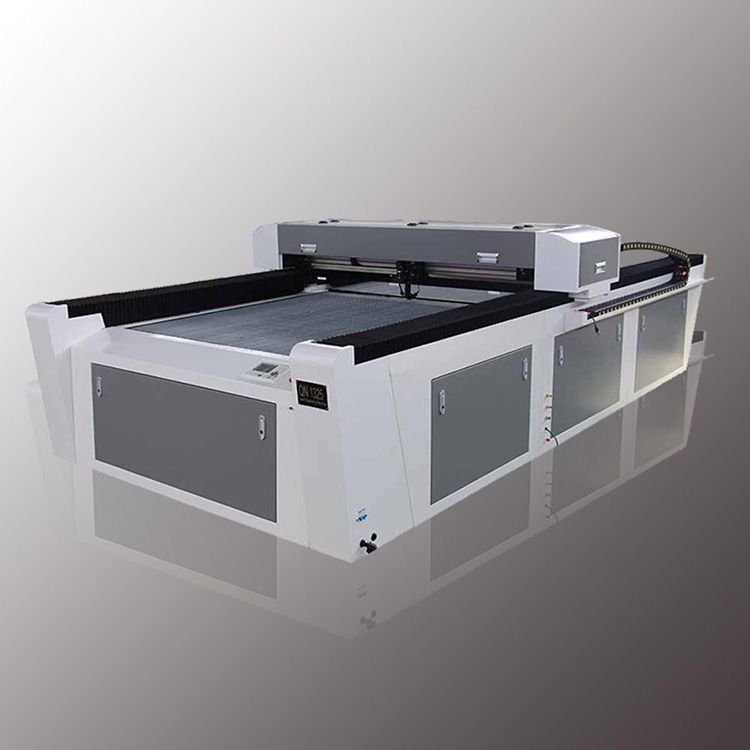

Large Format Co2 Laser Cutting Machine

Large Format Co2 Laser Cutting Machine is a comprehensive solution for cutting large size materials. Whether for display and shop fittings, architectural model making, membrane keyboard production, printing service providers, display making, sign processing or technical textiles and furniture manufacturing, our SP laser systems are designed to operate 24/7, allowing you to be fast and reliable work.

Send Inquiry PDF DownLoad

Large Format Co2 Laser Cutting Machine Features

SUNNA laser cutting machine is designed for fast and accurate processing of large format materials. Features such as four-sided channels and Tandem Assist are combined with maximum cutting speed to ensure maximum productivity. Use the entire work area with no free time. Thanks to RIP and CAD compatibility, the laser cutter can be seamlessly integrated into your prepress workflow.

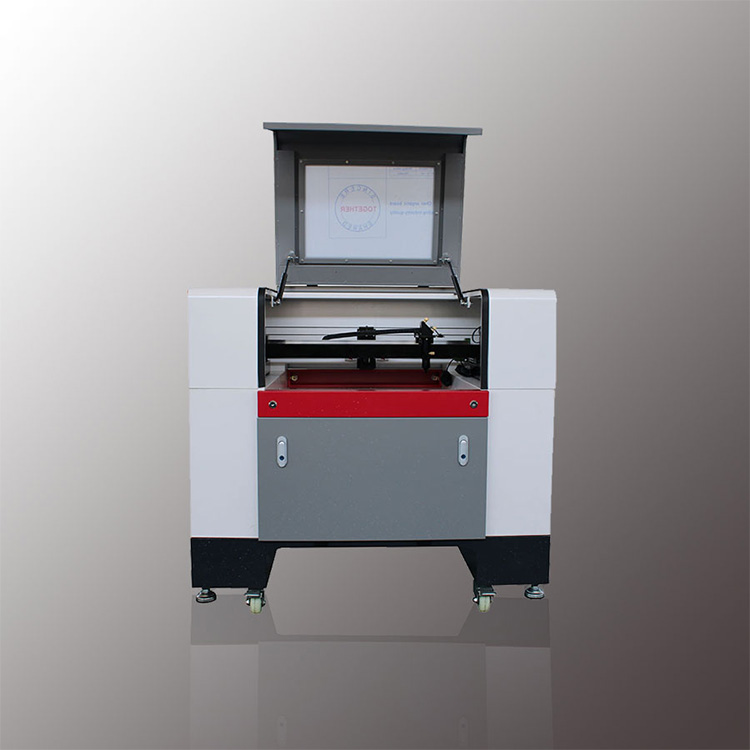

1. Imported linear motion guides are used to ensure the durability of the machine. (Taiwan PMI or Japan CSK)

2. The optical lens adopts a high-strength gold-plated silicon wafer and aspheric focusing lens. Therefore, the lens is resistant to paint and high temperature and does not need to be replaced frequently, which greatly reduces the cost of use. The small focusing diameter of the aspheric lens makes the cutting effect better.

3. All-optical frames are simple in structure design, easy to adjust, and easy to maintain the lenses. (Optical subdivision threaded knob)

4. Adopt DSP motion control system, running smoothly. Modular unified design, installation, strong anti-interference ability, easy to repair and replace accessories.

5. The laser tube adopts forced water cooling, automatic temperature control, and water shortage alarm to ensure that the laser tube can work continuously. (CW5200 model)

6. Knife bar aluminum profile tabletop fence type is convenient for picking up and cutting.

7. Emergency stop switch device.

8. Filter, improve the anti-interference of the machine.

9. DC switching power supply.

10. Chinese and English operation panels can be selected arbitrarily.

11. Lightpath system that can be adjusted quickly.

12. Two 550W suction fans to ensure the removal of cutting smoke and dust.

13. Rack drive to ensure cutting accuracy.

14. Safety switch leakage protector to ensure personal safety.

15. Install the driver of the imported chip. (Strong stability of Leisai drive combination) 16. The mechanical system adopts a unique deceleration design, and the movement is stable and smooth. The cutting edges are smooth. The software adopts the continuous curve algorithm, and the cutting speed is faster.

Product Parameter (Specification)

| Model | SN-1325 |

| Worktable | Honeycomb or Aluminum knife |

| Engraving area | 1300x2500mm |

| Laser Power | 60W/80W/100W/150W/180W/200W/300W |

| Engraving Speed | 0-1200mm/s |

| Cutting Speed | 0-500mm/s |

| Cutting Depth (Acrylic) | 0-30mm |

| Resetting positioning accuracy | <0.01mm |

| Minimum Shaping Character | 1*1mm |

| Power Supply | 220V(or110V)+/-10% 50Hz |

| Software | Indirect output : ArtCut, Photoshop |

| Direct output :CorelDraw, AutoCAD, Lasercut, Laserwork, LaserCAD, RDworks | |

| Operation System | Windows XP/VISTA/Win 7/Win 10 |

| Cooling System | Water Cooling and protection system |

| Control system | Ruida System |

| Operating Temperature | 0-45℃ |

| Operating Humidity | 35-70℃ |

| Machine Dimension | 3200*2010*1150(mm) |

| Packing Dimension | 3360*2120*1400(mm) |

| Gross Weight | 1100kg |

Application

Applicable Industries: Model industry (construction models, aviation and navigation models and wooden toys), advertisement, decoration, arts and crafts, electronic and electric appliances, garment industry fabric leather cut, etc.

Working materials: Nonmetal materials such as acrylic, MDF, wood planks (light planks, paulownia wood), bamboo ware, double-color sheets, paper, leather, shells, coconut shells, ox horns, resin, animal grease, ABS boards, lampshade, etc.

Co2 Laser Engraving and Cutting Machine After Sales Service:

1.All of co2 laser Machine will be fully-checked by our quality control department before the shipment.We guarantee all of machines have a two -years warranty.

2.Training details: operation principles, system and structure, safety and maintenance, software the processing technique, and so on.

3. Numerous feedback from our clients have proven that our laser machines are stable in performance with rare malfunction. However, we would like to handle it as follows function occurs:

a.We guarantee that we will give you a clear reply within 24 hours.

b. Customer service staff will assist and guide you to analyze the malfunction in order to locate the cause.

c. If the malfunction is caused by improper operation on software and other soft faults, we will help solve the problem online.

d.We will offer plenty of online supports, just like detailed technical and installation instructions by email,video, whatsapp,wechat (Training by team viewer)

We are a factory and our prices are the most competitive. We are in Shandong, China. Welcome to our factory. If you have more questions, please feel free to ask us.

We have a strictly quality inspection department. Our engineers will carefully check and test the machines many times before we deliver them to you. Before delivery, we will also send the startup operation video to you for confirmation.