- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

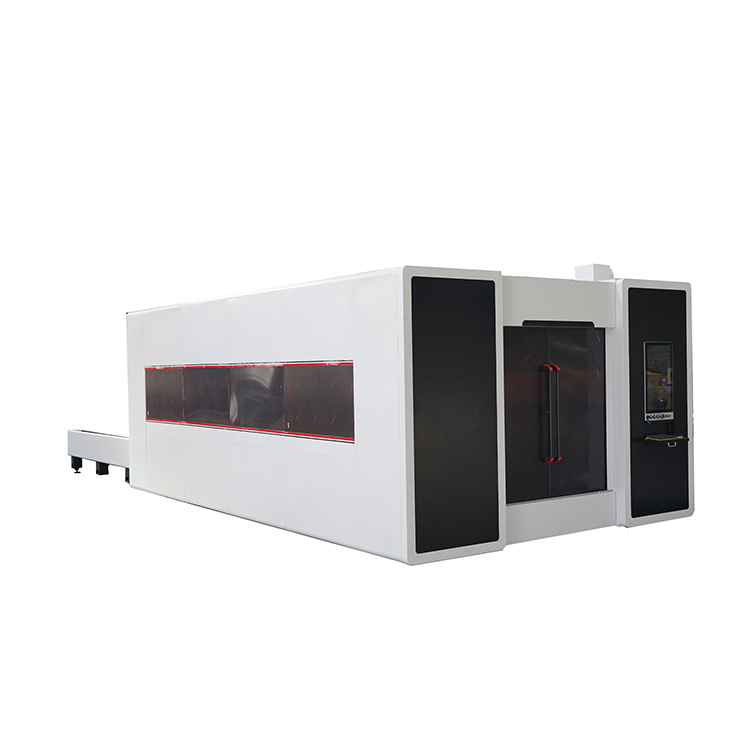

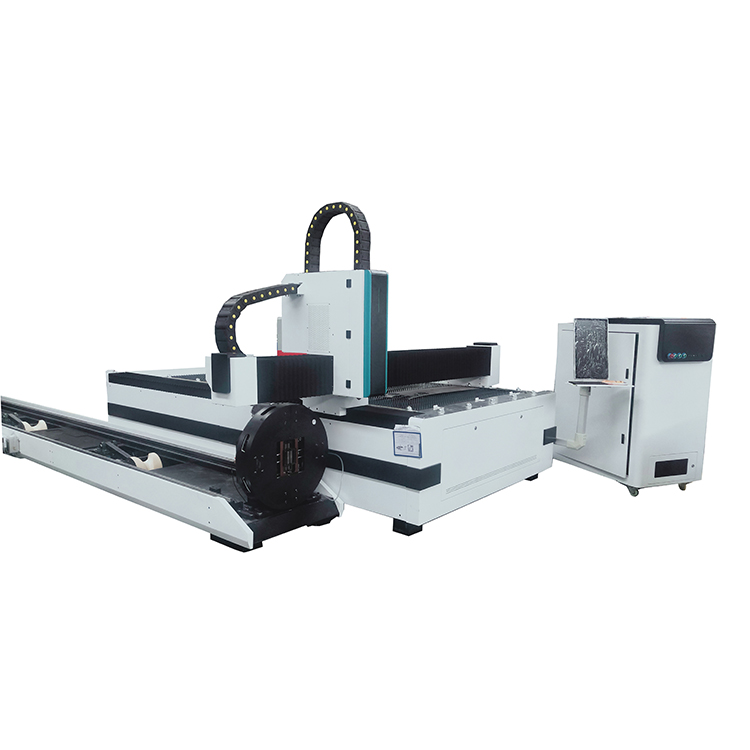

Industry Enclosed 3015 Fiber Laser Metal Cutting Machine

As a supplier specializing in manufacturingIndustry Enclosed 3015 Fiber Laser Metal Cutting Machine, you can rest assured that you can buy fiber laser cutting machine from our factory, SUNNA will provide you with the best after-sale service and timely delivery. This fully enclosed fiber laser cutting machine has a fully enclosed design, together with the actual laser protection glass, which makes the machine more safe and reliable. Suitable for cutting aluminium, brass, galvanised sheet, etc.

Send Inquiry

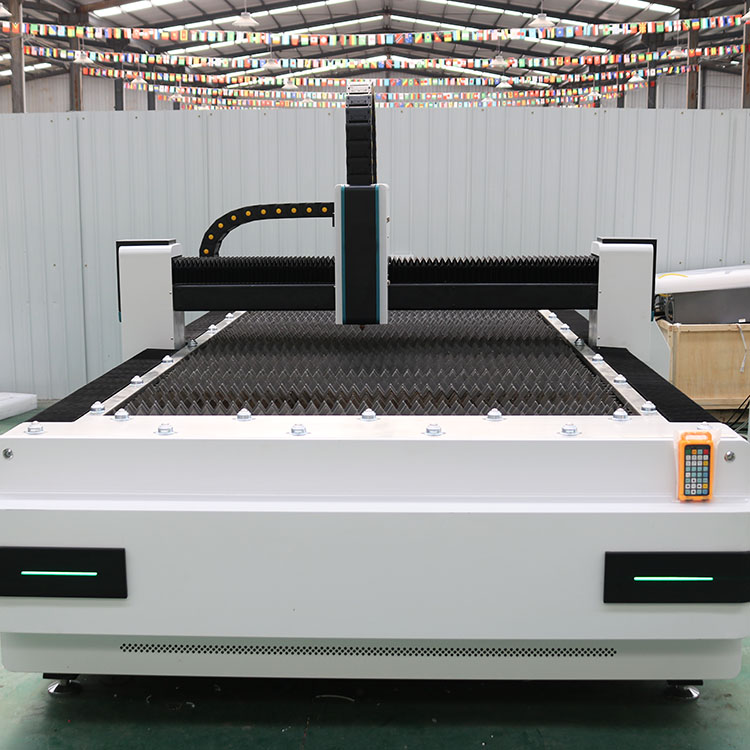

The power consumption of SUNNA Industry Enclosed 3015 Fiber Laser Metal Cutting Machine is only 20-30% of similar CO2 laser cutting machine. Enclosed design is also a common approach in laser cutting machines. Enclosed design makes the process safer and more friendly to the environment, suitable for cutting aluminium, brass, galvanised sheet. It adopts imported AC servo drive, fully enclosed frame drive, imported linear information direction, gantry structure, high damping bed, aluminium alloy extrusion buckle, which can withstand high rhythm and acceleration; it adopts industry-leading modern platform switching device, which provides commercial storage of 100,000 hours, basically maintenance-free, and the non-contact laser cutting head is equipped with an imported capacitive peak monitoring device, which ensures the function of the cutting focal point, and avoids the collision with the sheet material for processing.

Product Parameter (Specification)

| Model | SN-3015F |

| Transmission | TAIWAN RAIL AND RACK |

| Laser Power | 1.0kw 1.5kw 2.0kw 3.0kw 4.0kw 6.0kw, 8.0kw, 12.0kw |

| Working Area |

SN3015F - 5'W x 10'L SN4020F - 6'W x 13'L SN6020F - 6'W x 20'L |

| Control Software | Cypcut Control System |

| Cutting accuracy | 0.01mm |

| Fiber Laser Head | Raytools Cutting head |

| Gross Power | 15KW |

| Machine Weight | 14000KG |

| Voltage | 380V,50Hz |

| Cutting Gas | Compressed air, oxygen, nitrogen |

| Cooling System | WATER COOLING |

| Driving System | YASKAWA SERVO MOTOR |

| Automatic Grade | Automatic |

| Phase | Three phase |

| Max. Acceleration | 1.5G |

| Application | Mild Steel, Carbon Steel, Stainless Steel, Aluminum, Brass sheet tube cutting |

| Power Source | Raycus/IPG/MAX |

| Max Running Speed | 4000 IPM | 6000 IPM (Optional) |

| Max.Cutting Speed | 30,000mm/min |

| Autofocus | Yes |

| Cutting Thickness | 0 to 20mm (mild steel) |

| Support File Extension | Plt, bmp,dxf, jpg, tif, ai |

| Package Dimension | 1 x 40GP |

| Gross Weight | 2500KGS |

What is the Maximum Cutting Thickness ?

| 1KW | 1.5KW | 2KW | 3KW | 4KW | |

| CS(mm) | 0.4-12 | 0.4-16 | 0.4-18 | 0.4-20 | 0.4-25 |

| SS(mm) | 0.4-5 | 0.4-6 | 0.4-8 | 0.4-12 | 0.4-12 |

| Aluminum (mm) | 0.4-3 | 0.4-5 | 0.4-6 | 0.4-8 | 0.4-12 |

| Brass (mm) | 0.4-3 | 0.4-5 | 0.4-6 | 0.4-6 | 0.4-8 |

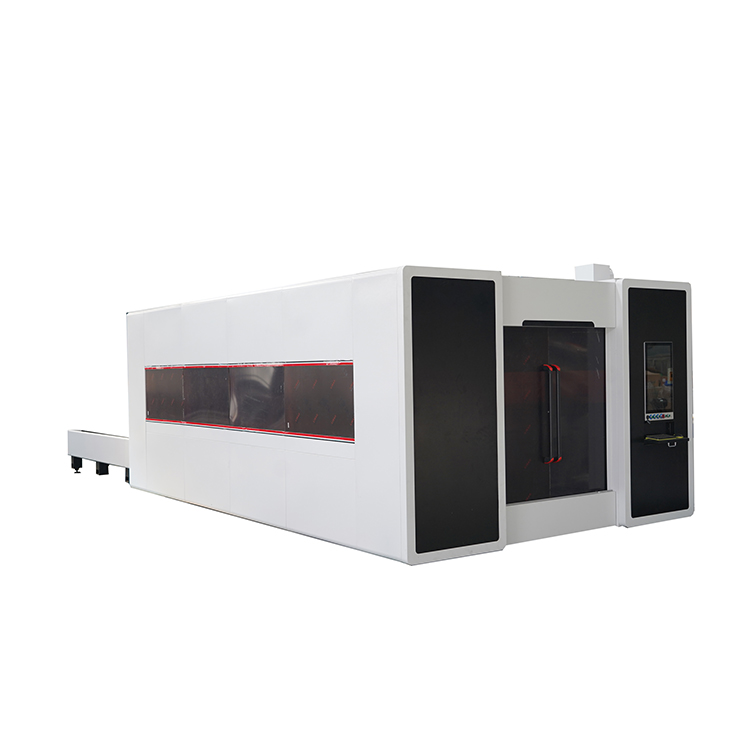

Enclosed Sealed Fiber Laser Cutter Main Feature

1. Separated control cabinet, more easier to dismantle when delivery machine. Also easy for installation.

2. Two holes for connect exhaust fan, 1 on enclosure, another on machine body, standard specs. Also provide customers 2 exhaust fans.

3. The front and rear bed stitching changed to angle steel splicing. And it has double fixed support. Those improvements ensure exchange table has higher stability. Besides, the exchange time is up to 15 seconds.

4. The table frame limit is all in one type, and the position is at the front and at the rear bed ends. It will be more earlier for adjustment.

5. The new model table frame is fixed by the cylinder down-stroke press lock. The fixing is more reliable and precise, also can be adjusted.

6. Add guide frame on exchange table chain, to make sure running more stable.

7. Standard specs. With 2 monitors. The controller and monitor layout more better.

8. New design enclosure consist of few parts, very easy to install. Each parts with wheels and guide frame.

9. Inside enclosure, there are enough space to walk, easy for maintenance.

Enclosed Sealed Fiber Laser Cutter Main Parts Introduction

-

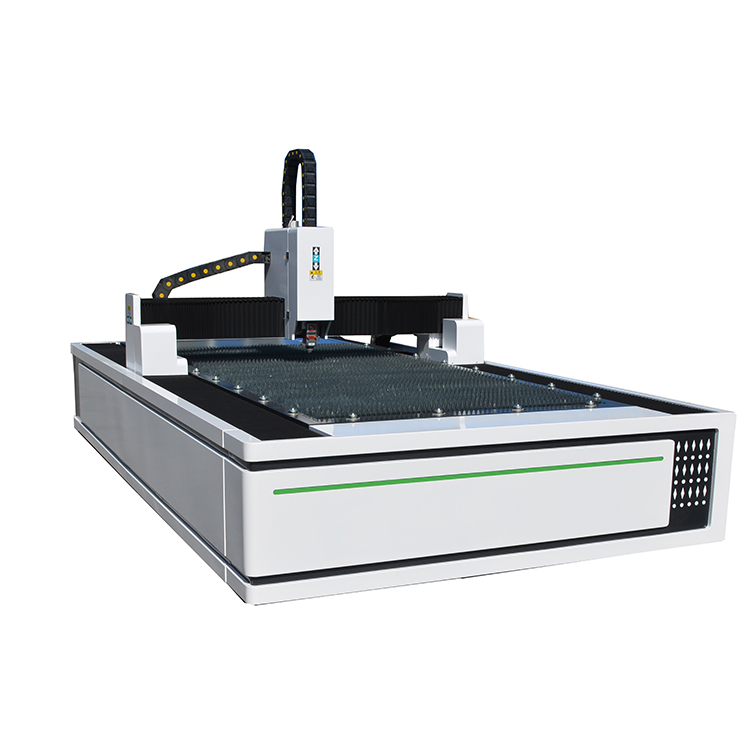

CAST-IRON BED, ANTI-VIBRATION, STABLE, NO DEFORMATION

--The main frame adopts the gantry structure welded by all steel plates to ensure the long-term stability without deformation.

--Improve the stability and rigidity of the Y-axis beam.

--Using gantry rack double guide rail, double servo drive structure.

--Ensure the high precision and high dynamic performance of Y-axis beam movement. --Y-axis beam runs smoothly at high speed, greatly reducing gas consumption.

-

Full protective cover

--It is equipped with two sets of raw material pallets and finished material pallets to realize the cost-effectiveness of automatic transfer and return to the warehouse, and meet the needs of medium, large and small varieties of plates.

--The whole line can realize full-automatic intelligent operation to ensure that the production process is unattended

--The storage space of the eight layer cargo space frame meets the storage requirements of various plates and the return function of finished products.

-

CYPUT CONTROL SYSTEM

--Support AI, DXF, PLT, Gerber, LXD and other formats, and accept the Cyput international standard G code generated by MaterCam, Type3, Wentai and other software.

--To use the easiest way to set the lead, slotted compensation, micro connection, bridge-connection, lead inside or outside, lead seal without gap and so on.

-

GEARS, RACKS, GUIDES

--The guide rail and rack are calibrated by a precision collimator with an accuracy of ±0.02mm

--Using Taiwan YYC rack, grinding on all sides. And there is a positioning pin design to prevent the rack from shifting

--Using Taiwan HIWIN guide rail, and use oblique pressure block design to prevent displacement of guide rail

-

SWITZERLAND RAYTOOLS AUTO-FOCUS LASER CUTTING HEAD

--AUTOFOCUS: Through the built-in drive unit of the servo motor, the focusing lens is driven by the linear mechanism to automatically change the position in the focusing range.

--EFFICIENT: Reading the saved cutting parameters through the operating system can quickly change the focus position of the laser head, eliminating manual operation and improving efficiency by 30%

-

FAMOUS BRAND LASER SOURCE

--We have professional sales and technician who can suggest you the most suitable laser source, depending your target price.

--Stable performance and high cost performance

--The fiber launch is stable, with long service life of nearly 100,000 hours

--It can run continuously 24 hours a day to meet the requirements of industrial continuous production

-

CONTROL CABINET

All the electrical components are housed and wired in a doubled-doored electrical enclosure. This allows for easy access and service when needed. All wiring is tagged so that when service is required, the customer can easily navigate the cabinet

-

HIGH QUALITY SERVO MOTOR

Composed of: servo drives and the servos move in all axes.With this motor, the machine can realize high-precision machining at high speed.

-

WATER CHILLER

The function of the water cooler is to reduce the temperature of the laser generator and prevent the laser from being burned out.We only use brand-name water coolers with reliable quality.

Applicable Industry and Materials

Fiber Laser Stainless Steel Cutting Machine is suitable for stainless steel, carbon steel, silicon steel, aluminum alloy, titanium alloy, galvanized steel, pickle plate, aluminum-plating Zinc plate, metallic copper and other metals.

Specially used for cutting 0.5-30mm carbon steel sheets (pipes), 0.5-15mm stainless steel sheets, galvanized steel(pipes), electrolytic zinc-coated steel sheet(pipes), silicon steel(pipes) and other kinds of thin metal sheets and pipes. Range of pipe diameters: 20-220mm.

Fiber Laser Cutting Machine After Sales Service:

A.SUNNA INTL will supply fiber laser cutters with training videos and user's manuals in English for installing, operation, maintenance and trouble-shooting, and shall give technical guide by e-mail,whatsapp,wechat,telegram,teamviewer,telephone and so on, when you meet some problems of installation, using or adjusting.

B.You can come to our factory for training. SUNNA will offer professional guide. Direct and effective face-to-face training. Here we have assembled equipments, all sorts of tools and testing facility,we will also provide accommodation during training period. Training Time: 1-10 working days.

C.Engineers service machinery overseas

With rich experience, SUNNA provides customers with the best after-sales service and support in the industry, and helps customers when they need it most. The minimum order quantity is one, and you can customize the style and color you like. With the purchase of a SUNNA machine, customers receive free email and phone technical support for life, which means we are here when you need us.