- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

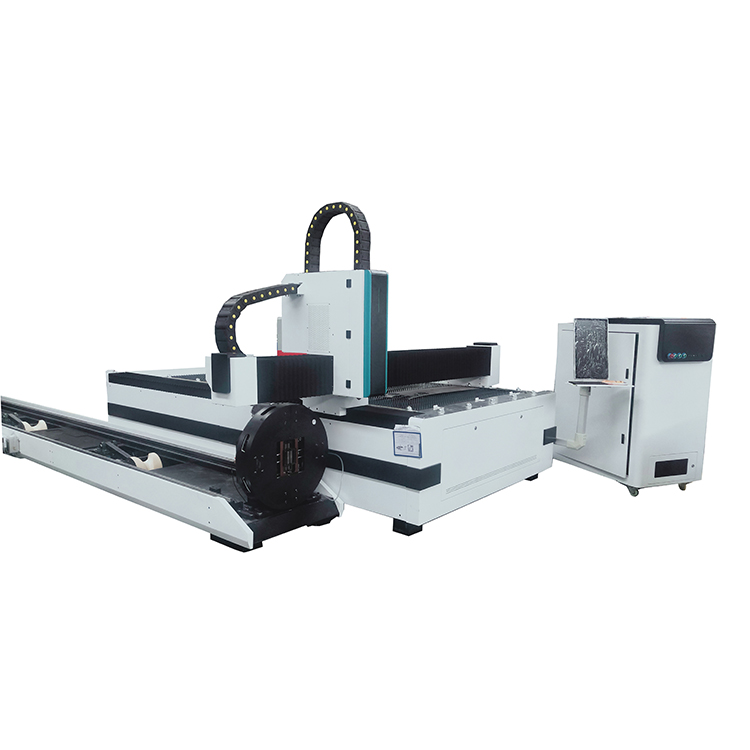

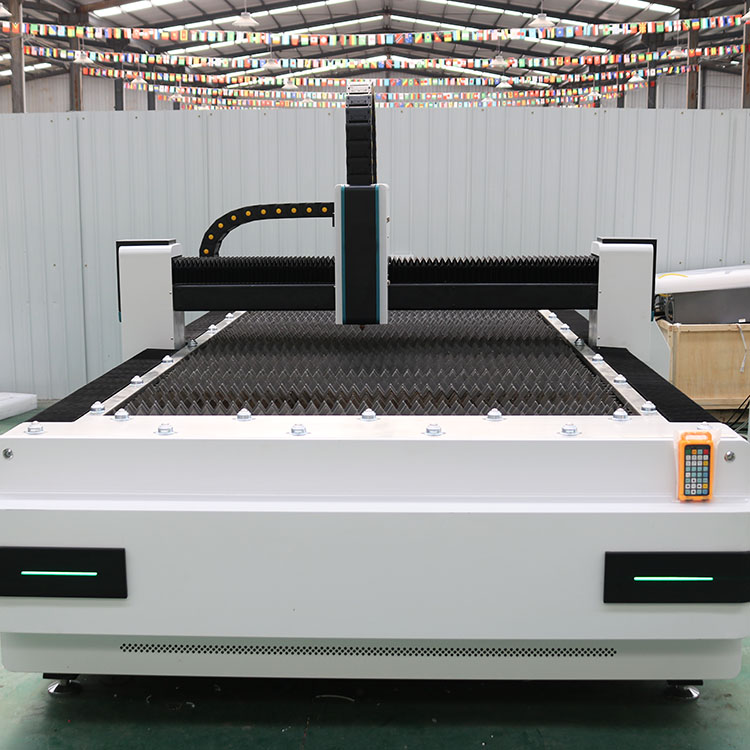

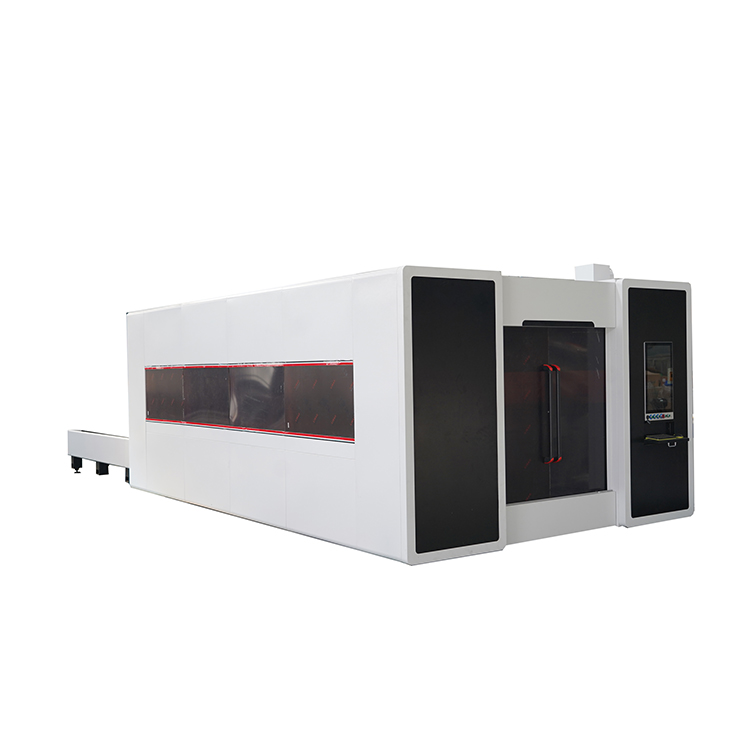

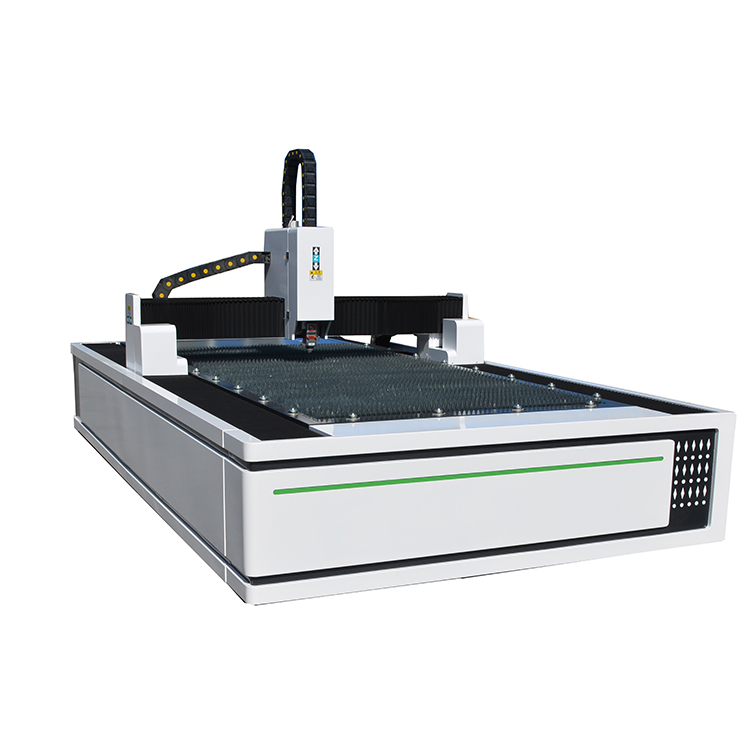

Fiber Laser Pipe Tube Metal Sheet Cutting Machine

This SUNNA 5aixs 1000w Fiber Laser Pipe Tube Metal Sheet Cutting Machine is aimed at metal processing tubes and plates. With five-axis perfect cutting, it can cut round pipe, square pipe, channel, angle steel, etc. If you need metal pipe cutting, welcome to buy SUNNA 5aixs 1000w fiber laser pipe tube metal sheet cutting machine.

Send Inquiry

SUNNA 5aixs 1000w Fiber Laser Pipe Tube Metal Sheet Cutting Machine is powerful, fast, efficient, high precision and stable operation, which is your best choice for cutting metal pipes. SUNNA 5aixs 1000w fiber laser pipe tube metal sheet cutting machine adopts powerful control system, high quality accessories and professional technicians. High factory acceptance requirements for the whole machine ensure that you receive high quality and trouble-free SUNNA 5aixs 1000w fiber laser pipe tube metal sheet cutting machine.

Product Description of 5 Axis Fiber Laser Pipe Tube Metal Sheet Cutting Machine

This machine is used for cutting metal round and square tubes, channel steel,H beam,angle steel, etc. It adopts a 19-inch high-resolution LCD color display, which can display cutting graphics and cutting running tracks. Cutting programs can be edited manually. It adopts five-axis perfect cutting, which can cut round pipe, square pipe, channel steel and angle steel. In addition, it supports functions such as pause, forward, backward, and speed regulation during processing. It can store 200G files and can be used at will. It is driven by high-efficiency servo motor, with fast speed, high efficiency, high precision and stable operation. High-flexible shielded wire is used to truly resist high-frequency interference. It is suitable for various fiber optic models. The movable beam can save tailings. The front chuck is equipped with two sets of intelligent follow-up splicing devices to facilitate the For long material processing requirements, there is a set of intelligent follow-up material support systems in between, so as to avoid Buyer’s long material sagging and affecting the cutting accuracy.

Product Parameter of 5 Axis Large Optical Fiber Laser Cutting Machine

1.Excellent beam quality: Smaller focus diameter , high work efficiency, better processing quality.

2. High cutting speed: 2-3 times faster than YAG and CO2 laser .

3.High Stability: Adopt superior quality fiber laser, stable performance, key parts can reach .

4. High efficiency for photoelectric conversion : Compared with CO2 laser cutting machine, Fiber laser cutting machine has 3 times photoelectric conversion and with energy saving & friendly environment .

5. Low cost: The whole power consumption is only 20-30% of traditional CO2 laser cutting machine.

6.Low maintenance cost: It is with Optical fiber line transmission, no need reflector lens, can save a lot of maintenance cost.

7.Easy Operation : Fiber Line transmission, no adjustment of optical path.

8.Super-flexible optical effect : small volume, compact structure, easy to flexible manufacturing requirements.

| Equipment model | SN-5012 |

| Laser type | fiber-optic laser |

| Laser working medium | optical fiber |

| Laser wavelength | 1060-1080 nm |

| RATED OUTPUT POWER | 300W/500W/750W/1000W/1500W |

| Beam quality | <0.373mrad |

| X-axis distance | 120mm |

| Y-axis distance | 5000mm |

| Z axis distance | 120mm |

| Effective cutting range | 3000*1500mm |

| Positioning accuracy | ≤±0.02mm/m |

| Repeat positioning accuracy | ≤±0.02mm/m |

| Max. Moving speed | 120m/min |

| Support graphic format | PLT,AI,BMP,DST,DXF format (support for CORELDRAW, AI,PHOTOSHOP, AUTOCAD) |

| Power Supply | 3P, AC 380V/50Hz/16A |

Detailed images of 5 Axis Large Optical Fiber Laser Cutting Machine

CYPCUT CONTROL SYSTEM

--Support AI, DXF, PLT, Gerber, LXD and other formats, and accept the Cyput international standard G code generated by MaterCam, Type3, Wentai and other software.

--To use the easiest way to set the lead, slotted compensation, micro connection, bridge-connection, lead inside or outside, lead seal without gap and so on.

GEARS, RACKS, GUIDES

--The guide rail and rack are calibrated by a precision collimator with an accuracy of ±0.02mm

--Using Taiwan YYC rack, grinding on all sides. And there is a positioning pin design to prevent the rack from shifting

--Using Taiwan HIWIN guide rail, and use oblique pressure block design to prevent displacement of guide rail

SWITZERLAND RAYTOOLS AUTO-FOCUS LASER CUTTING HEAD

--AUTOFOCUS: Through the built-in drive unit of the servo motor, the focusing lens is driven by the linear mechanism to automatically change the position in the focusing range.

--EFFICIENT: Reading the saved cutting parameters through the operating system can quickly change the focus position of the laser head, eliminating manual operation and improving efficiency by 30%

FAMOUS BRAND LASER SOURCE

--We have professional sales and technician who can suggest you the most suitable laser source, depending your target price.

--Stable performance and high cost performance

--The fiber launch is stable, with long service life of nearly 100,000 hours

--It can run continuously 24 hours a day to meet the requirements of industrial continuous production

CONTROL CABINET

All the electrical components are housed and wired in a doubled-doored electrical enclosure. This allows for easy access and service when needed. All wiring is tagged so that when service is required, the customer can easily navigate the cabinet

HIGH QUALITY SERVO MOTOR

Composed of: servo drives and the servos move in all axes.With this motor, the machine can realize high-precision machining at high speed.

WATER CHILLER

The function of the water cooler is to reduce the temperature of the laser generator and prevent the laser from being burned out.We only use brand-name water coolers with reliable quality.

Application field of 5 Axis Large Optical Fiber Laser Cutting Machine

Fiber laser cutting machines are used in various manufacturing and processing industries such as aviation, aerospace, automobiles,precision parts, metallurgical external processing, and kitchenware processing.

After-sales service 5 Axis Large Optical Fiber Laser Cutting Machine

1.fiber laser cutting machine 3 years warranty except consumable parts;

2.Plenty of technical support online is available;

3.Quick Back-up Parts Available&Technical Assistance;

4."Training Video","Instruction Book",and"Operation Manual"will be offered;