- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

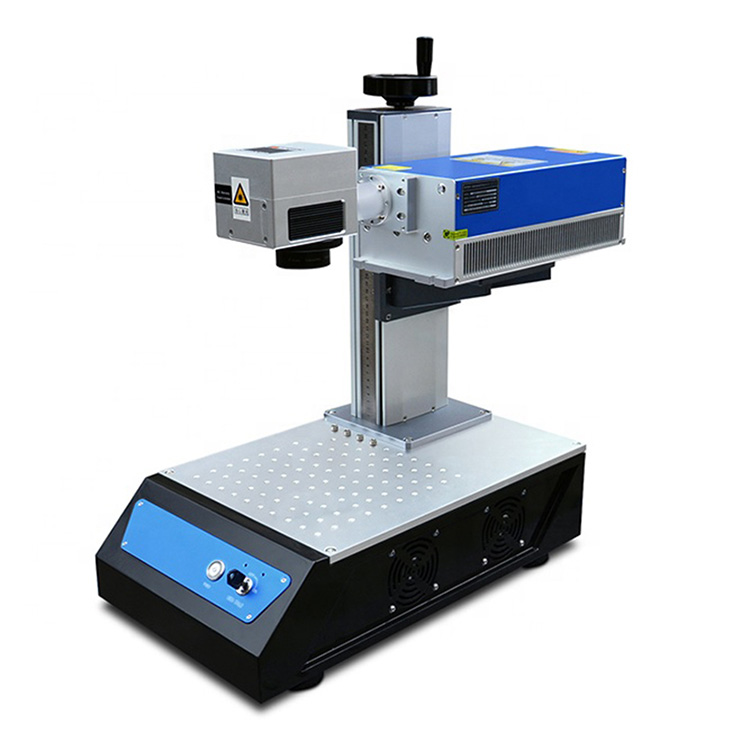

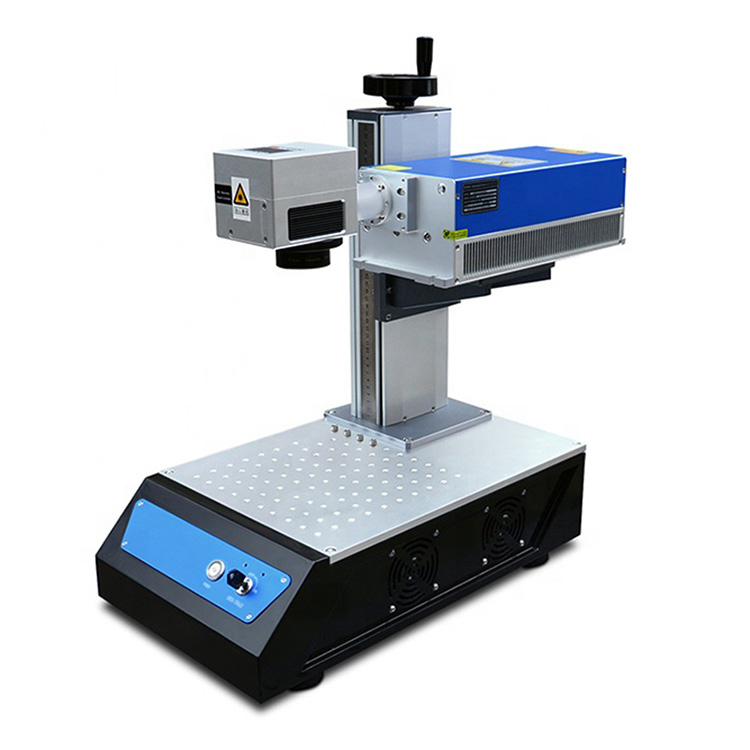

Enclosed Cabinet Portable Plastic Parts Metal Steel Uv Laser Marking Machine

SUNNA's Enclosed cabinet portable plastic parts metal steel uv laser marking machine utilizes state-of-the-art laser technology to achieve high-precision, high-definition marking results. Whether it's text, patterns or 2D codes, they will be displayed on your products in stunning detail. Discover our Enclosed cabinet portable plastic parts metal steel uv laser marking machine that brings lasting marking and value to your ideas and products.

Send Inquiry

SUNNA Enclosed cabinet portable plastic parts metal steel uv laser marking machine is suitable for a wide range of materials, including plastic, metal, ceramic, glass and more. Whether you manufacture industrial parts or cosmetic products, our machines are perfect for your marking needs.The enclosed design of the SUNNA Enclosed cabinet portable plastic parts metal steel uv laser marking machine effectively controls laser radiation to ensure safe operation while providing an efficient production environment. It also provides an efficient production environment. The high speed marking function enables you to complete large quantities of marking in a short period of time, improving production efficiency. And our UV laser marking machines have user-friendly interfaces and simplified operating procedures that allow you to quickly master the art of operation. Don't miss your chance to own an Enclosed cabinet portable plastic parts metal steel uv laser marking machine, contact SUNNA today!

Enclosed UV Laser Marking Machine Introduction

Closed design ensures dust-free processing. Conducive to machine maintenance. It is especially suitable for marking objects with large volume or heavy weight that are inconvenient to handle.

Enclosed UV laser marking machine is developed with 355nm Ultraviolet laser source for plastic, silicon, glass, ceramic, which adopts a third-order intracavity frequency doubling technology. Compared with infrared lasers, 355nm UV laser has a very small focus spot, which can greatly reduce the material mechanical deformation and processing heat influence is small. UV laser marking machine are mainly used for ultra-fine marking and engraving. It is especially suitable for food and medical packaging materials, marking, micro-holes, high-speed division of glass materials, and complex pattern cutting of silicon wafers.

Enclosed UV Laser Marking Machine Parameter (Specification)

| Model No. | SN-UV-3W/5W |

| Laser type/wave length | 355nm |

| Laser output power | 3W/5W |

| Beam quality㎡ | <1.1 |

| Marking speed | 400 characters per second |

| Working area | 110×110mm or 150×150mm ( adjustable ) |

| Machine power | 600W |

| Power supply | 380V/50-60Hz or 220V/50-60Hz |

| Minimum character | 0.1mm |

| Repeated accuracy | ±0.001mm |

| Minimum line width | 0.015mm |

| Life of the laser machine | ﹥100,000 hours |

| Cooling system | Water Cooling |

| Control interface | Standard USB |

| Overall dimensions | 560*330*680mm |

Enclosed UV Laser Marking Machine Feature and Application

It has advantages such as short wavelength, short pulse, high-quality light beam, high precision and high peak power, etc. Therefore, the system has excellent application characteristics in special material processing fields to avoid thermal effect and increase processing precision obviously on various sufaces.

● High security

Designing enclosed laser optical path, can effectively prevent the leakage of laser radiation

● High stability

Increase the stimulated oscillation, reduce energy loss, good stability to ensure increased product quality

● High speed

Perfect hardware and software,with high-speed imported galvanometer, the marking speed can up to 7000mm / s, effectively improve production capacity.

● Good beam quality

Due to the small focus spot and the small heat affected area , especially suit for fine and precise marking.

● High performance

It has the characteristics of high photoelectric conversion efficiency, long service life of nonlinear crystal, stable operation of the whole machine, high positioning accuracy, high operation efficiency and no fading of marking.

UV Laser Marking Machine Main Parts

-

High Speed Galvanometer

High Speed Galvanometer

-

EZCAD Software

EZCAD Software

-

High Precision Field Lens

High Precision Field Lens

-

Laser safety glasses

Laser safety glasses

-

High Quality Leadshine stepper motor

High Quality Leadshine stepper motor

-

Well-known Brand Switching Power Supply

Well-known Brand Switching Power Supply

Application

It is widely used in electronic components, battery chargers, electric wire, computer accessories, mobile phone accessories (mobile phone screen, LCD screen) and communication products.

Automobile and motorcycle spare parts, auto glass, instrument appliance, optical device, aerospace, military industry products, hardware machinery, tools, measuring tools, cutting tools, sanitary ware.

Pharmaceutical, food, beverage and cosmetics industry.

Glass, crystal products, arts and crafts of surface and internal thin film etching, ceramic cutting or engraving, clocks and watches and glasses.

It can be marked on polymer material, majority of the metal and non-metallic materials for surface processing and coating film processing, pervious to light polymer materials, plastic, fire prevention materials etc

UV Laser Marking Machine After Sales Service:

1.All of UV Laser Marking Engraving Machine will be fully-checked by our quality control department before the shipment.We guarantee all of our laser marking machines have a two -years warranty.

2.Training details: operation principles, system and structure, safety and maintenance, software the processing technique, and so on.

3. Numerous feedback from our clients have proven that our laser machines are stable in performance with rare malfunction. However, we would like to handle it as follows function occurs:

a.We guarantee that we will give you a clear reply within 24 hours.

b. Customer service staff will assist and guide you to analyze the malfunction in order to locate the cause.

c. If the malfunction is caused by improper operation on software and other soft faults, we will help solve the problem on line.

d.We will offer plenty of online supports, just like detailed technical and installation instructions by email,video, telephone. (Training by team viewer)

4.Maintain Fiber Laser Marking Machine

In addition to the need for stable voltage, regular cleaning of the focus lens,and it does not require any maintenance.

CE certification & laser safety

SUNNA UV lasers comply with all applicable CE European machine guidelines and laser safety standards. Please note this is not the same as carrying a CE logo on the machine as can often be found on laser machines imported from China, this stands for 'China Export'. A large number of these laser machines do not comply with European machine guidelines and laser safety standards! Your supplier must always be able to show the underlying documentation and measurement reports. Theclosed UV lasersare Class 3R laser devices. This basically means that the operator and anyone in the same room can never be exposed to high power laser light. As a result, no further protective measures need to be taken, such as wearing certified laser safety glasses to protect the eyes. Theopen version is a laser class 4device in which extra laser safety measures must be taken at all times. SUNNA supplies approved laser safety glasses.