- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

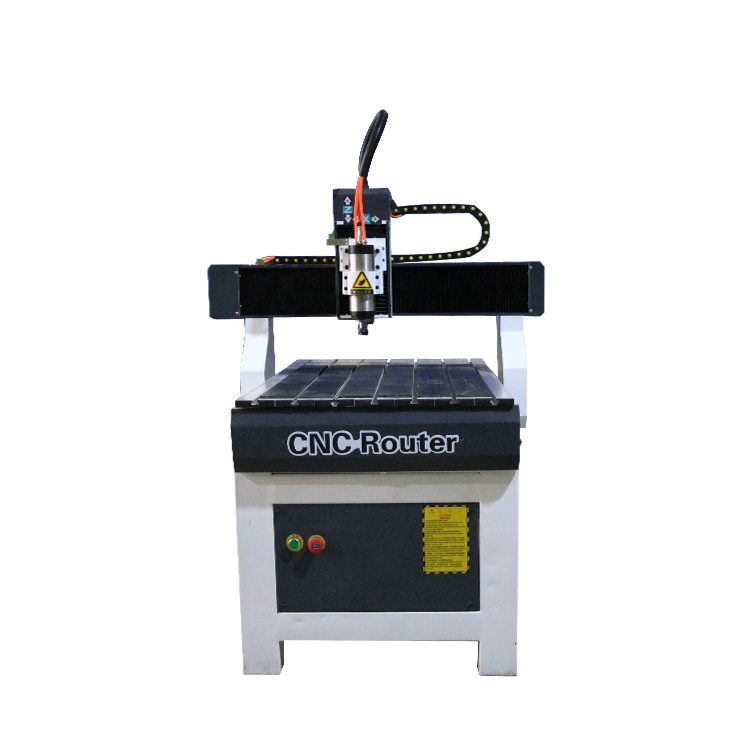

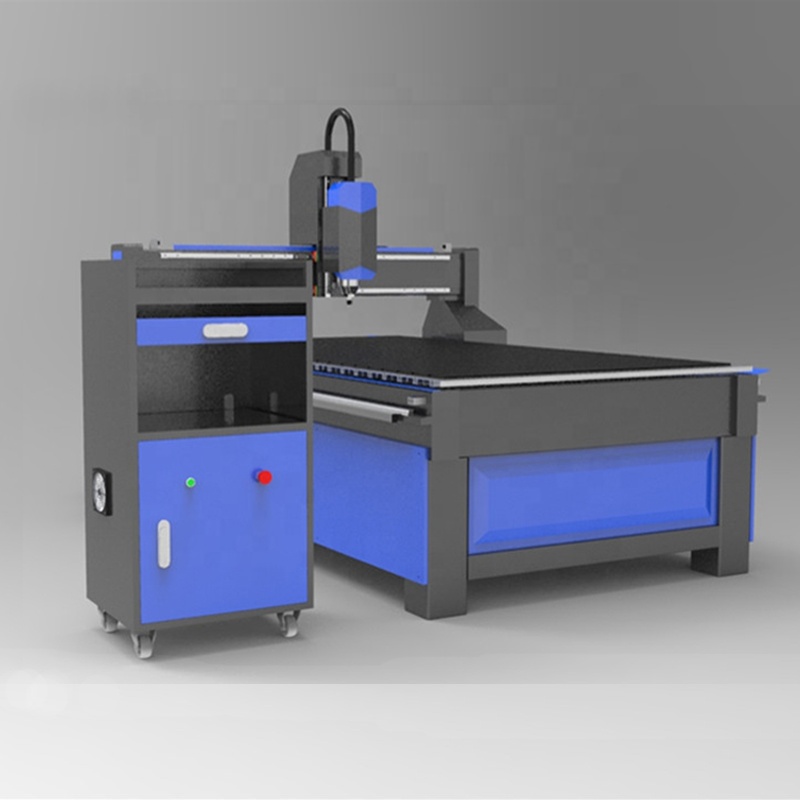

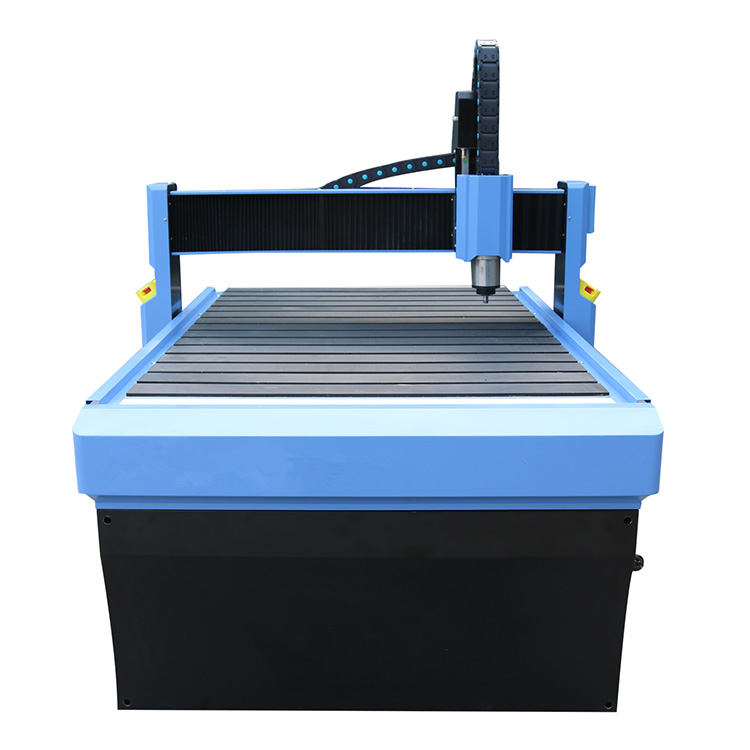

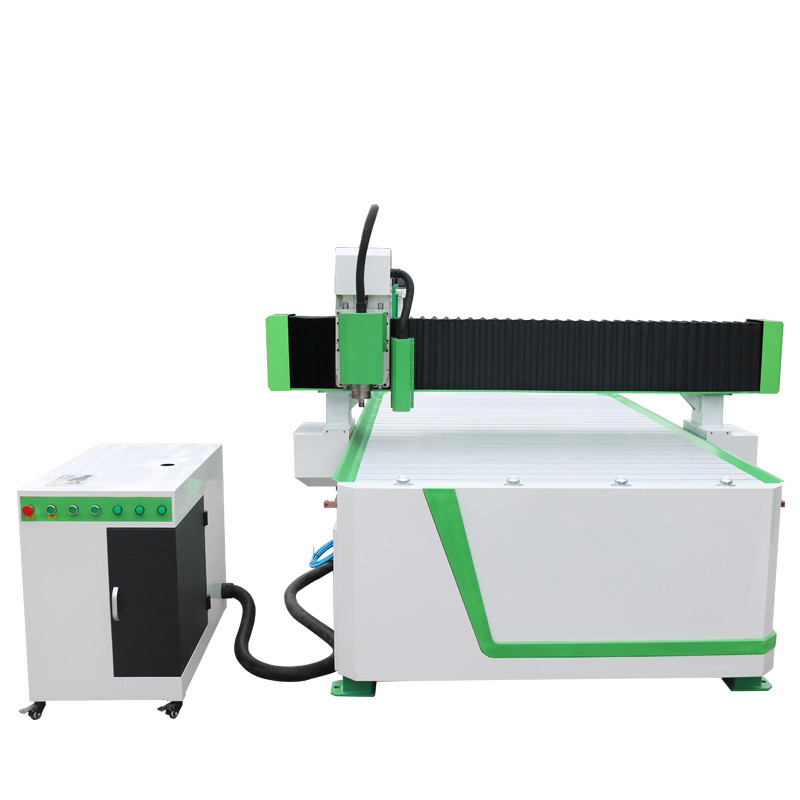

1325 CNC Automatic Tool Changer Woodworking Engraving Machine

SUNNA provides reliable, long-term solutions for your lumber, machinery, sign, automotive, marine or aviation business, providing the customizable CNC router you need. Our 1325 cnc automatic tool changer woodworking engraving machine offer you a wealth of value and customization flexibility, whether you need to process smaller wood chips, high-volume production of large sheet metal, or anything in between. Please contact the SUNNA team to start customizing your professional 1325 cnc automatic tool changer woodworking engraving machine.

Send Inquiry

SUNNA 1325 cnc automatic tool changer woodworking engraving machine is suitable for processing various complex products or multiple processing. It can be equipped with 6, 8, 10 or 12 tools according to the different production process requirements of customers. There are two ways of tool changing: linear tool changing and disc tool changing. SUNNA 1325 cnc automatic tool changer woodworking engraving machine has a wide range of uses, including engraving, milling, chamfering, side milling, drilling, cutting, grooving, etc. This CNC machine is ideal for light to heavy-duty manufacturing such as 3D foam, signage, wood, stone and metal processing. If you need more detailed information, please let us know as soon as possible and we will provide you with professional advice.

Automatic Tool Changing CNC Engraving Machine Introduction

The SUNNA ATC CNC router machine has two types of tool magazines: linear and carousel. Both of them can be installed beside the spindle or on the side of the machine bed. By changing different tools automatically, the ATC CNC machine can complete multiple and complex woodworking processes at one operation. It can realize cutting, carving, engraving, drilling, routing, grooving, and pocketing of wood, MDF, acrylic, PVC, plastic, foam, stone, soft metal and other materials. It is also called ATC CNC wood carving machine, wood engraving machine. Basic type 3 Axis ATC CNC can be upgraded to be 4 Axis, 5 Axis, Routary type, etc.

Description of Automatic Tool Changing CNC Engraving Machine

ATC CNC Router machine can complete multiple and complex woodworking processes at one operation. It can realize cutting, carving, engraving, drilling, routing, grooving, and pocketing of wood, MDF, acrylic, PVC, plastic, foam, stone, soft metal and other materials. It is also called ATC CNC wood carving machine, wood engraving machine.

Machine features :

1. SUNNA ATC adopts a heavy lathe body structure and crossbeam transmission design, main body with Industrial welding technology, quench dealing method, and then with high precision milling machine to build. All the accessories are all made one time by 5 axis machining center to ensure the machine's rigidity and accuracy.

2. X, Y-axis with imported high-precision rack, Z-axis with imported high-precision grinding grade ball screw.

3. Spindle with high precision, high speed, constant torque, low beating, strong stability, and long life characteristics.

4. Supporting G code and PLT code format generated by Type3, MASTERCAM, CASMATE, Artcam, AUTOCAD, UG, CorelDraw, and other CAD / CAM software.

China CNC Router HQD 9.0KW air-cooled spindle

The HQD 9kw frequency spindle on the ATC CNC router has adjustable speeds of up to 18,000 -24,000RPM.

All-Steel Reinforced Gantry

Rigidity has been increased for even higher accuracy. Vibration is reduced, and the longevity and dependability are increased.

High Precision Linear Guide

Linear motion is provided by rack and pinion on the x and y axes, and ball screw drive on the z axis. On all axes, the SUNNA Series CNC Router has 30mm or 25mm 20mm linear rail systems.

Oil mist/fog lubrication pump

It is driven by compressed air, sprays oil fog particles in the size between 0.5 and 15 0.5-15μm. It is application for lubrication and cooling of lubrication points. It is equipped with electromagnetic valve. When connected with main unit electric control, it can realize control of lubrication time.

Linear ATC

The tool changer magazine has as many as 8 tool positions, and a variety of combined tools are available at any time, and there is no need for operator intervention when changing tools during processing.

CNC Router Hand Wheel

Through wireless transmission technology to connect with the receiver, the operator can hold the handwheel, get rid of the connection of the spring wire, can walk freely, the operation is convenient, free, stable, and reliable, and the failure rate is reduced.

TBI Ball screw

High precision , durable and trustworthy without deformation

Vacuum Table

The T-slot vacuum table can absorb very small piece material.

Japan YASKAWA servo motor

Faster speed with signal feedback. Low heat radiation.

Run smoothly at ultra-low speed. Reduce the vibration, avoid oscillation.

vacuum pump 7.5 kw optional

※No oily odors.,Low noise and libration,Maintenance-free.

※High pressure and low noise

※Max dutput 4.66m³/min

※Ultimate vacuum: 0.097 Mpa

※Speed 1450rpm/min

Automatic Tool Changing CNC Engraving Machine Parameter (Specification)

| Description | Parameter |

| X,Y,Z Working Area | 1300x2500x200mm |

| Table Size | 1300×2500mm |

| X/Y axis max. rapid Travel Rate | 50-90m/min |

| X/Y axis max. working speed | 10-25m/min |

| Z axis max working speed | 6m/min |

| Table Surface | Vacuum and T-slot working table |

| Frame | Heavy Steel Tube Structure |

| X, Y Structure | Gear Rack transmission, Hiwin Rail Linear Bearings |

| Z Structure | Hiwin Rail Linear Bearings and TBI Ball Screw |

| Max. Power Consumption | (Without Spindle) 12.5Kw |

| Spindle Power | China HQD 9.0KW air-cooled spindle |

| Spindle Speed | 18000-24000RPM |

| Drive Motors | Japan YASKAWA servo motor |

| Inverter | 11kw Fuling inverter |

| Working Voltage | AC380V/50/60Hz, 3PH (Option: 220V) |

| Dust collector | 5.5Kw |

| Command Language | G Code |

| Operating System | Taiwan SYNTEC control System (Weihong is optional) |

| Computer Interface | USB |

| Collet | ISO30 |

| X,Y Resolution | <0.01mm |

| Software Compatibility | Type3/UcancameV9 Software, (Option: Artcam Software) |

Application:

Automatic tool changing CNC engraving machine is suitable for wood, acrylic, aluminum, copper, plastic, and carbon fiber composite materials, carving, and milling, widely used in soft metal and sheet metal processing areas.

SUNNA INTL After-Service:

The guarantee period of quality shall be 12 months counting from the date on which the commodity arrives at the port of destination.

We are responsible for offering the fittings free of charge during the guarantee period, while it is preferred you send the damaged fittings to us by courier with your charge for our testing, after confirming damage, we will send back the alternative fittings to you. After the guarantee of quality period, the parts required repairing or change, if any, shall be paid.

When you meet some complicated problem and online-support can not solve it, we can offer Door-Visiting Service. If our engineer to assemble or/and maintain or/and adjust the machine is/are required, we shall assist to deal with the visa formality and prepaid traveling expenses and accommodation to us during the business trip and the service period before their dispatch. And you can arrange for the translating person for the service engineer during their service period. Or you can send your engineer to China. We will offer long-term technical training to him for free.

Training, Commissioning & Start up of SUNNA CNC Router

We will supply with the machine Operation Manual and Training CD in English version for Installing and operation, including introduction for the composing of equipment, working principle equipment, common knowledge of computer, controlling principle of electronic devices, daily maintenance measures of equipment.Personal demonstration for installation, adjusting and operation of equipment, and the computer. Common malfunction eliminating measures, etc.

We will supply Instruction for simple troubleshooting of the machine when dispatching, which can help you dealing with the common problems happened unluckily. Also, one set of “Instruction Book”, “Operation Manual” and “Training Video Disk” for machine/software will be sent to you along with the machine,which could be easily understood and friendly handled by you and your customers.

ODM/OEM customized projects allocate sufficient resources to ensure the first response, efficient collaboration with customers, shorten the research and development cycle, and help customers quickly realize product marketization.

MQ:1 SETS